Martin

SSEA Pneumatic Benchtop Pressure Pumps

The SSEA pneumatic benchtop pressure pumps to generate pressure and vacuum

The SSEA pneumatic benchtop pressure pumps to generate pressure and vacuum

- for the testing, adjusting and calibration

- of mechanical and electronic pressure instruments, (gauges, switches, transmitters)

- comparing the unit to test with a master.

The tests can be carried out in laboratories, workshops or on site at the set measuring point.

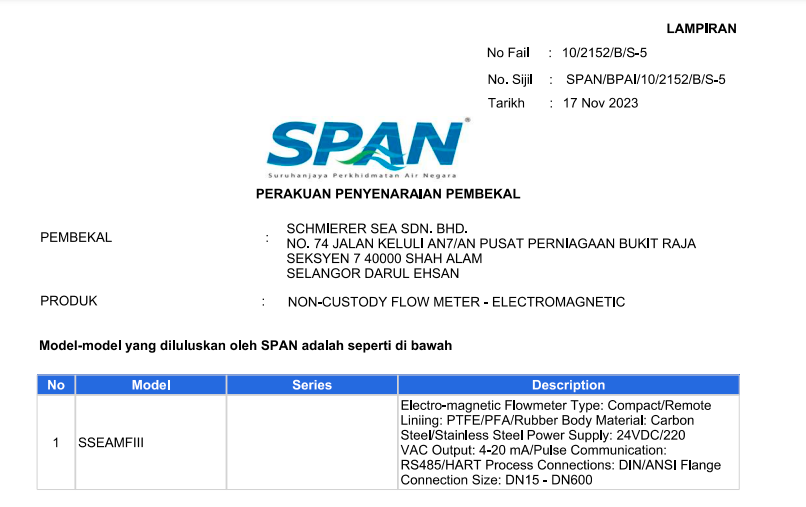

SPAN approval for SSEA electro-magnetic flowmeter

Type: Compact/Remote

Type: Compact/RemoteLining: PTFE/PFA/Rubber

Body Material: CarbonSteel/Stainless Steel

Power Supply: 24VDC/220VAC

VAC Output: 4-20 mA/Pulse

Communication: RS485/HART

Process Connections: DIN/ANSI Flange

Connection Size: DN15 - DN600

The SPAN Approval complies with the requirements for the Water and Waste Water Industries in Malaysia.

Clamp-on flowmeters for small pipes

The SSEA UCOFM ultrasonic clamp-on flow meter for small pipes (DN 15-50). Supply and Consumption flow monitoring for clean liquids: clean fluids: water, acids, alcohols, chemical solvents, beverages, etc.

The SSEA UCOFM ultrasonic clamp-on flow meter for small pipes (DN 15-50). Supply and Consumption flow monitoring for clean liquids: clean fluids: water, acids, alcohols, chemical solvents, beverages, etc.

- easy and fast installation and retro fitting - clamp-on, no pipe cutting

- no flow interruption during installation and maintenance

- no moving parts - no wear and tear

- factory defaults for standard setup, touch buttons

- flow monitoring on unit, display options m3,l, GAL, min, h, etc.

- Totalizer, Alarm, output options

Flash Pasteurization Process System

By flash pasteurization harmful microorganisms in soft drinks and mineral water are killed with the aim of improving microbiological stability and shelf life of the product. Flash pasteurization is a well-established and cost-effective process in beverage industry.

By flash pasteurization harmful microorganisms in soft drinks and mineral water are killed with the aim of improving microbiological stability and shelf life of the product. Flash pasteurization is a well-established and cost-effective process in beverage industry.

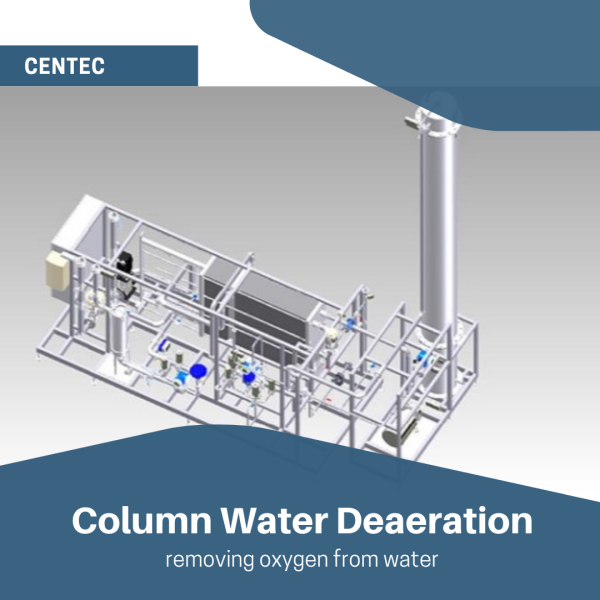

Water Deaeration Process System

Dissolved oxygen has adverse impact on flavour stability and shelf life. The deaerations system DeGaS Hot or Cold removes O2 from water that is used for the production of soft drinks and mineral water. For hot deaeration, the water is heated and disinfected at the same time, Cold deaeration is performed at ambient temperature.

Dissolved oxygen has adverse impact on flavour stability and shelf life. The deaerations system DeGaS Hot or Cold removes O2 from water that is used for the production of soft drinks and mineral water. For hot deaeration, the water is heated and disinfected at the same time, Cold deaeration is performed at ambient temperature.

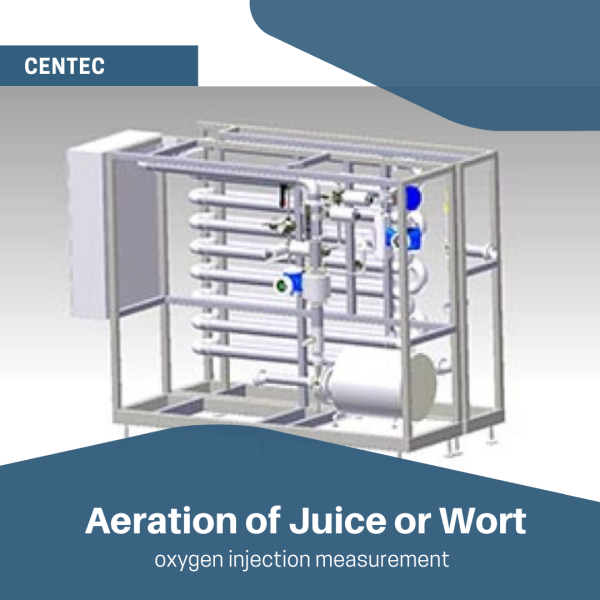

Aeration of Juice Process System

The Juice Aerator (or Wort Aearator) is used for the continuous and highly accurate injection of oxygen or sterile air into fruit juice. For yeast reproduction and growth and consistent fermentation, the specified oxygen content needs to be exactly reached.

The Juice Aerator (or Wort Aearator) is used for the continuous and highly accurate injection of oxygen or sterile air into fruit juice. For yeast reproduction and growth and consistent fermentation, the specified oxygen content needs to be exactly reached.

Additive Dosing Process System

The additive dosing system ADoS is used for dosing of ingredients such as vitamins, flavours and colours directly into the main product stream. The compact skid provides a high degree of flexibility for the production of different products.

The additive dosing system ADoS is used for dosing of ingredients such as vitamins, flavours and colours directly into the main product stream. The compact skid provides a high degree of flexibility for the production of different products.

Multi Component Mixing Process System

The MultiMixer is used for the continuous mixing of several streams of liquid products, e.g. deaerated water, syrup and flavours. Since the number of blending channels can be adapted to individual needs, the skid provides a high degree of flexibility for the production of different products.

The MultiMixer is used for the continuous mixing of several streams of liquid products, e.g. deaerated water, syrup and flavours. Since the number of blending channels can be adapted to individual needs, the skid provides a high degree of flexibility for the production of different products.

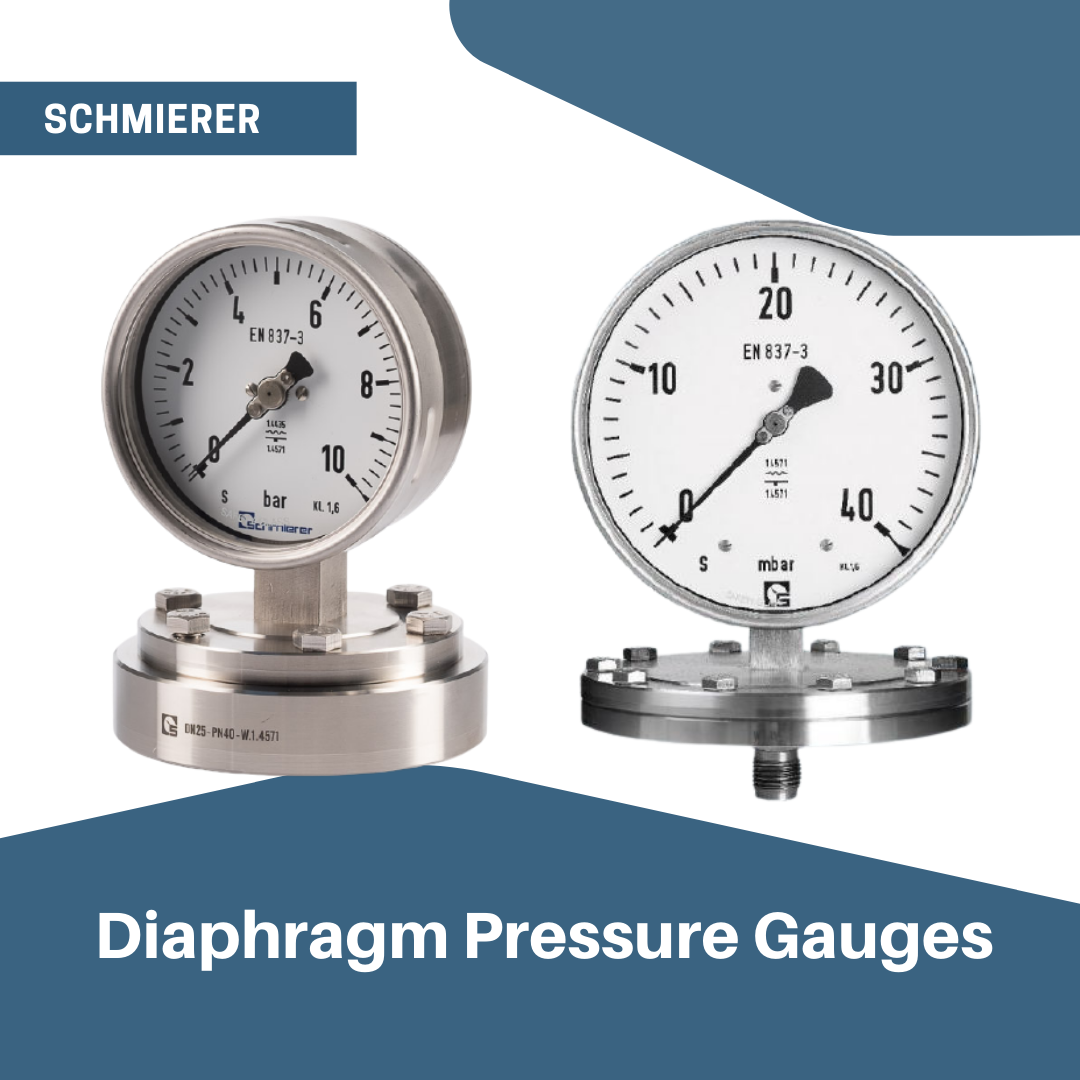

4 advantages of diaphragm pressure gauges

Schmierer Diaphragm PG have 4 advantages to overcome the limitations of the commonly used Bourdon Tube technology: low pressure - overload protection - aggressive & high viscosity media applications.

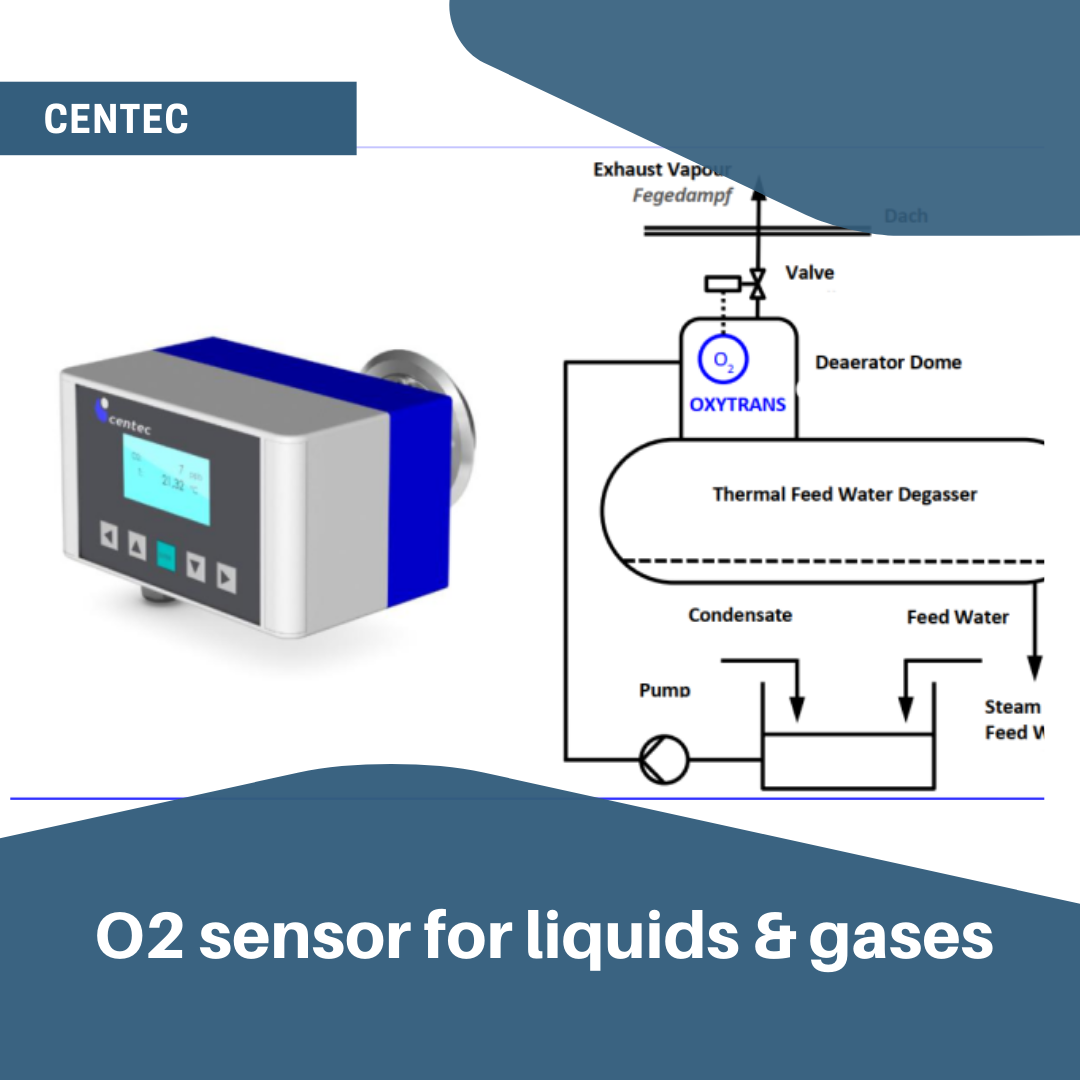

Oxytrans - continuous O2 measurement in liquids and gases

OXYTRANS/OXYSTEAM is a very precise, optical oxygen sensor from Centec, Germany to continuously monitor dissolved oxygen (O2) in liquids and gases for:

OXYTRANS/OXYSTEAM is a very precise, optical oxygen sensor from Centec, Germany to continuously monitor dissolved oxygen (O2) in liquids and gases for:

- steam boiler water degassing to avoid corrosion

- boiler feed water

- protective atmospheres

- deaerated water, soft drinks, wort

- liquid food and dairy products (flavor stability, shelf life)