ITABAR PITOT TUBE

The measuring principle of a Pitot Tube is based on the theory of differential pressure. A simple, though effective measurement method, combining low installation and operation cost with great reliability, for Gas, Liquid and Steam Flow monitoring.The measuring principle of a Pitot Tube is based on the theory of differential pressure. A simple, though effective measurement method, combining low installation and operation cost with great reliability, for Gas, Liquid and Steam Flow monitoring.Itabar Steam Flow Sensors are designed to operate in environments with temperatures up to 650°C and 400 bar pressure. Itabar Liquid and Gas Flow Sensors are designed to operate in environments with temperatures up to 1175°C and 400 bar pressure. The process connection can be threaded or flanged. Intra Automation offers the choice of different sensors, depending on line size and flow. The WinFlow calculation software is applied in the determination of the sensor size.

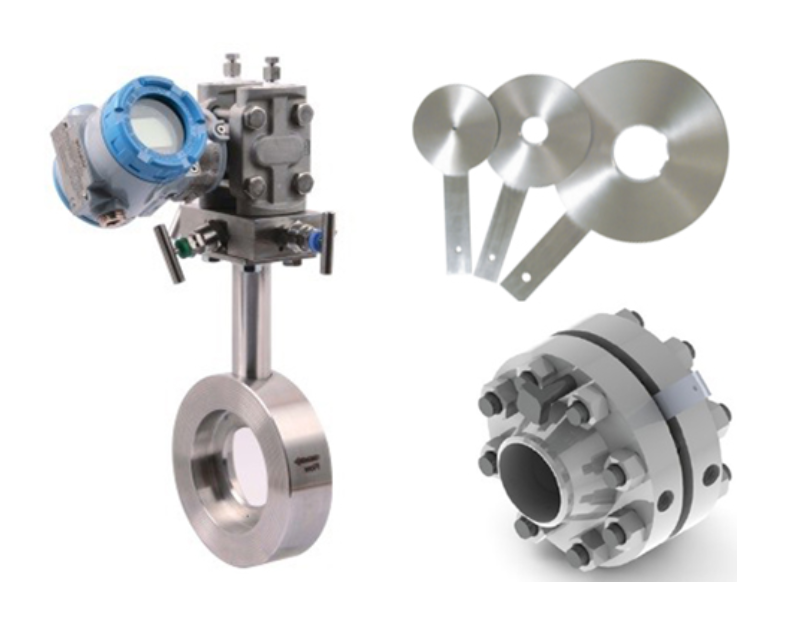

ORIFICE and ORIFICE ASSEMBLIES

Orifice plates are used for flow rate measuring in pipe systems. With orifice plates a pressure drop is created. Orifice plates are used for flow rate measuring in pipe systems. With orifice plates a pressure drop is created. Based on the value of the pressure drop the flow rate can be calculated. Orifice plates are produced in accordance with ISO 5167. All the above items are available in C.S., SUS, PTFE, PVC, others on request.In combination with differential pressure transmitter Integral Orifices are suitable for measuring fluid of small bore where high accuracy is required. Integrated flow meters reduce welding and installation times as fittings, tubing, valves, adapters and mounting brackets are not needed.

Orifice plates are used for flow rate measuring in pipe systems. With orifice plates a pressure drop is created. Orifice plates are used for flow rate measuring in pipe systems. With orifice plates a pressure drop is created. Based on the value of the pressure drop the flow rate can be calculated. Orifice plates are produced in accordance with ISO 5167. All the above items are available in C.S., SUS, PTFE, PVC, others on request.In combination with differential pressure transmitter Integral Orifices are suitable for measuring fluid of small bore where high accuracy is required. Integrated flow meters reduce welding and installation times as fittings, tubing, valves, adapters and mounting brackets are not needed.

VENTURI TUBES

Whenever pressure loss is an issue, Venturi Tubes are a good alternative to Orifice Assemblies and Flow Nozzles.Venturi tubes are designed and produced on customers request. The significant advantages of venturi tubes are the high pressure recovery and maintenance free design. Used for applications which do not support high pressures and therefore do not allow much pressure loss. Allows flow-measurements of gases, steam, water, condensates and slurries.

FLOW NOZZLES

Flow Nozzles are an alternative to orifice plates whenever it comes to the measurement of high speed flows.Flow Nozzles are an alternative to orifice plates whenever it comes to the measurement of high speed flows.Its unique design features gives an exceptional strength, allowing a 60% higher flow rate. Compared with the venturi tube, the flow nozzle is cheaper, whereby the pressure recovery is not as high. Similar to venturi tubes, flow nozzles are maintenance free. Used for applications which do not support high pressures and therefore do not allow much pressure loss. Allows flow-measurements of gases, steam, water and condensates.

CONE

Cone Flow Meters can be used in a great variety of applications: liquids, gases, steam, slurries, etc.

- High accuracy (± 0,5 % of the measured value) is achievable

- Wide Turndown Ratio: 10:1

- Minimal in- and outlet requirements, provided by a pipe run.

- Low pressure loss (compared with orifice plates of the same β)

- Self-cleaning (due to the form of the cone behind the flow element a partial vacuum is generated, which avoids abrasion on the flow element .

WEDGE TUBE

Compared to other fluid meter using differential pressure flow meter, the Wedge Tube has a shorter length of straight pipe for upstream & downstream with excellent repeatability and accuracy. Wedge Tube can be manufactured according to end user‘s specification.Compared to other fluid meter using differential pressure flow meter, the Wedge Tube has a shorter length of straight pipe for upstream & downstream with excellent repeatability and accuracy. Wedge Tube can be manufactured according to end user‘s specification.

Intra Automation offers a wide range of Flow Computers, Displays, Transmitters, Switches and Accessories for Flow Calculation, Monitoring and Control.

BYPASS

The bypass flow meter operates on the differential-pressure method. A ring with an orifice plate is installed in the pipeline. The orifice plate causes constriction of the flow and effects a drop in pressure. This pressure drop is proportional to the square of the flow rate.

If the pressure tap upstream of the orifice plate is connected by a pipe to that downstream of the orifice plate, a partial flow will flow through that pipe. This partial flow is proportional to the flow rate in the main pipeline.

The partial flow can be turned on and off, as required, by installing two ball valves in the bypass line.

The low-cost device in PVC is frequently used in swimming-pool water technology. The device in PVDF is suitable for the flow measurement of aggressive media, e.g. in water treatment, while the stainless steel type is mainly used for flow measurement of air and gases. The measuring range extends from 0.02 - 0.16 m3/h to 300 - 1800 m3/h for H20, and from 0.15 m3/h - 1.5 to 1200 - 6000 m3/h for air at STP.