Coriolis Mass Flow Technology

HIGHEST PRESSURES, HIGHEST TEMPERATURES, MOST EXOTIC MATERIALS, MOST VERSATILE SENSORS – NO COMPROMISE IN PERFORMANCE / QUALITY / SUPPORT.

With highly accurate measurement performance and extreme capabilities, Rheonik meters are a natural choice for many applications and quickly provide payback through improved product quality and greatly reduced maintenance. Whether used for transfer, batching, process feed or control, Rheonik meters can provide online flow and density measurement.

- Liquid, sludge and gas measurement capability

- Models to measure fow rates from as low as 0.03 kg/h up to 1,500,000 kg/h (0.07 lb/h to 3,300,000 lb/h)

- Sizes up to 12”/DN300

- Pressure ratings up to 900bar/13,050psig

- Temperature ratings from -255°C to 400°C/-425°F to +750°F

- Fiscal/custody transfer approvals (OIML R117/NTEP)

- ATEX and CSA hazardous area approvals covering most of the world

- Extreme resistance to gas bubbles entrained in the process stream when compared to conventional Coriolis meters

- Unafected by viscosity, density or pressure changes

- Multifunction measurement capability includes density and temperature

- Available with stainless steel, hastelloy, monel and tantalum wetted materials as standard. Other materials on request

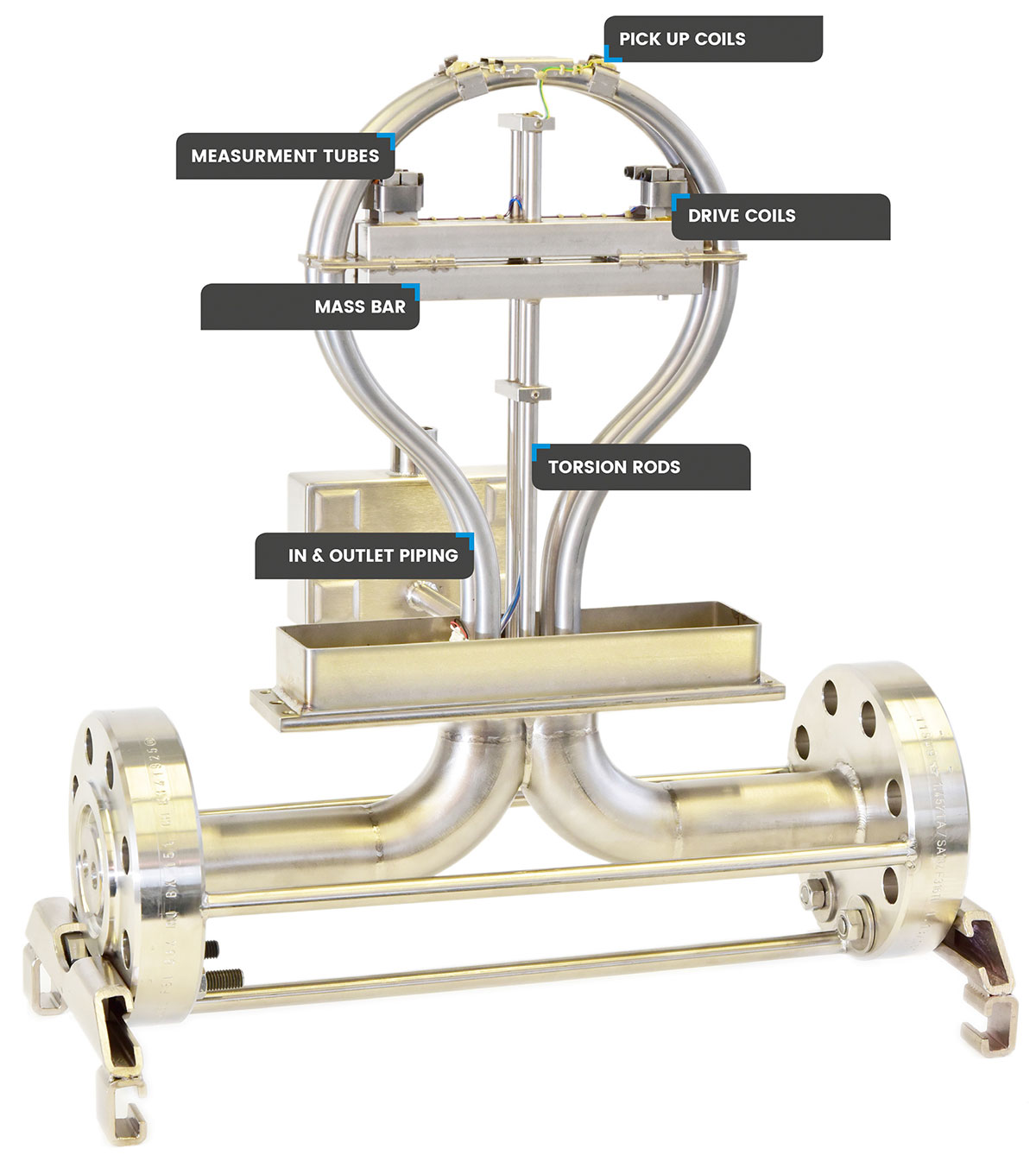

Coriolis Technology is based on a unique torsional oscillator. Other than conventional Coriolis sensors, the Rheonik sensor offers a torsion axis enhanced oscillation translating into a better measurement.