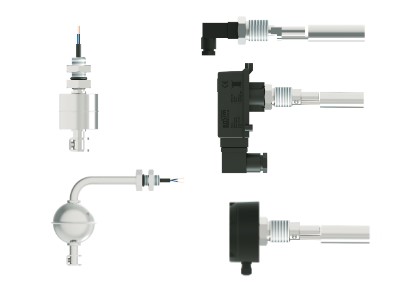

Paddle Switches

Paddle flowswitches detect flow or no flow of water, lubricating oils, gases and aggressive media inside a pipe without the need of cooling the liquid:

Working Principle:

When the magnetic field in the float is aligned with the reed sensor in the tube it opens or closes the The paddle in the stainless steel body is moved with the flow of the fluid. With no flow it returns to the contact closed position. The magnet in the reverse pole of the paddle triggers a signal in the micro switch. The factory contact switch position can be manually reversed.

Mini Switches

Mini Level Switches are economic and easy to install devices with minimal space requirements. They are used for level measurement in machines, tanks, boilers, etc. for both liquids and gases.

The Switches can be made by Plastic (PP, PVDF, PBT, Delrin) or stainless steel.

Working Principle:

When the magnetic field in the float is aligned with the reed sensor in the tube it opens or closes the electric ciruit. When the float moves away, the sensor reverts back.

Diaphragm Switches

Level control with a membrane is the most economical method in measurement of level of bulk material in the storage. It can be used in open and non-pressure tanks. The diaphragm switch can check full, empty and loaded situations of powdered, dusty, corny, granular, grained bulk materials in the grain elevator. It is appropriate for using particles with 0,3 and 2,5 t/m³ and up to max. 30 mm. The Membrane must be in contact with the material.

Working Principle:

As long as material, which is poured to the grain elevator, accumulates, the membrane is closed. The material pushes membrane back with composed press and mechanism pushes the contact. Contact gives audible alarm or sends a signal to stop the filling mechanism of the grain elevator. When the material precipitates and reduces, the contact reverts back. Precision setting is made during assembly by sliding the mechanism.

Cable Level Switches - Float Type

Cabled level switches are used for tank, depot, waste water plant level control in the industrial facilities. They operate without any problem in the this environment with its mechanical design and there is not any jam. Neoprene rubber cable is used for resistance against different liquids and in order that it does not crack in the hot-cold ambient.

Application Fields:

Fish ponds, swimming pools, groundwater, waste mater pools,treatment pools, plunger pump applications, residential water tanks,etc... Water, waste water, diesel, fuel oil, glycerine, gas, nitric acid 10%,acetic acid 10%, formaldehyde 40%, lactic acid 10%, hydrochloride 10%,sulphuric acid 30% etc...

E-Tilt Level Switches

E-TILT sensors are used vertically. They are used to stop the water leakage by commanding the relay outlet to a solenoid valve or to send a warning signal to a siren.

Application Fields:

Conveyor belts, silos, telescopic arms for ship loading

Optical Level Sensors

Optical Level Sensors consist of an infrared sensor and an optical receiver. Light from the sensor is broken by reflection from the prismatic surface and sensed by the receiving unit. Light return intensity changes according to air or liquid cover of the prismatic surface. The change is measured, calculated and triggers the switching outlet. It can be mounted from any angle to the tank, horizontal connection is recommended. It requires less maintenance and is not affected by conductivity or consistence of the liquid.

Applications:

Alcohol, Ether, Water, Acid, Mineral Oil, Lactic Acid