SEA Regional Diaphragm Seal (DS) Service

As a German - Malaysian joint venture we are pleased to announce that we have set up a diaphragm seal filling station in Shah Alam in June 2016. With this new service we will be able to locally assemble standard and specialized Diaphragm Seals (DS) to:

- new Pressure Transmitters, Switches and Gauges

- used Pressure Instruments with mal-functioning DS

- all brands, models and manufacturers

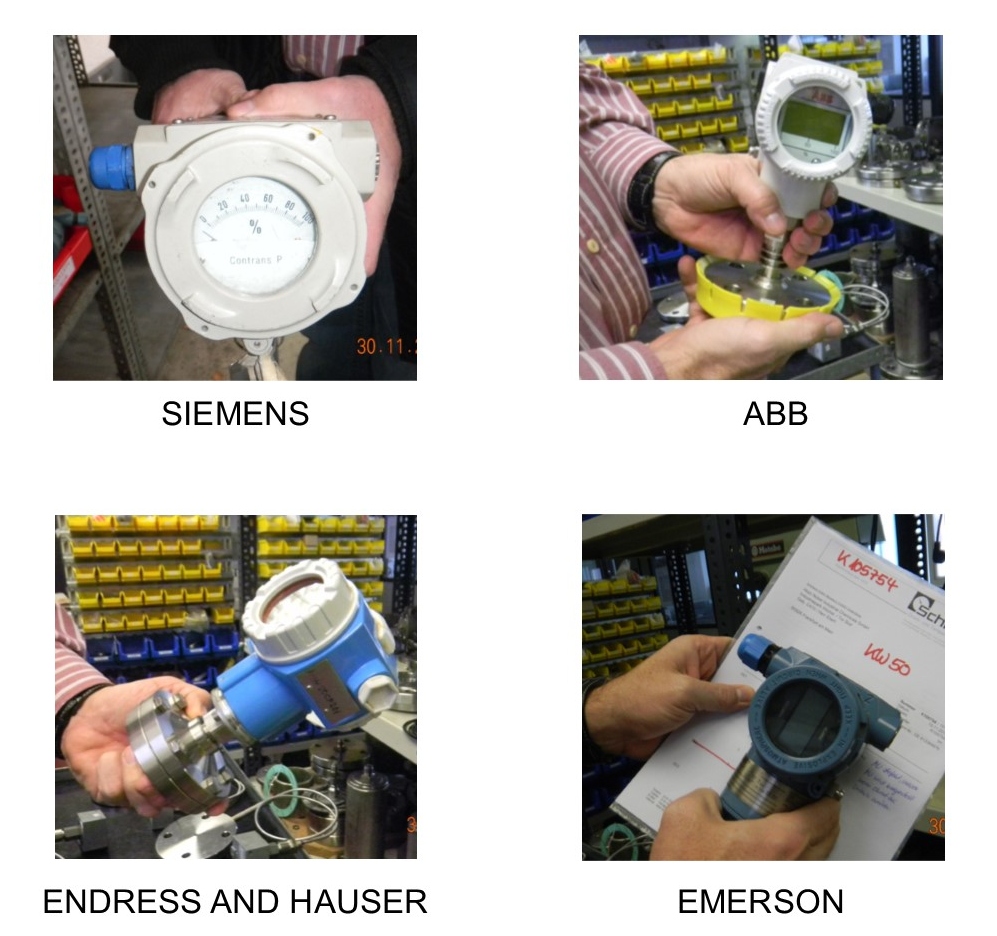

Pressure Instruments with Diaphragm Seals

DS replacement for branded Pressure Transmitters

How does a Diaphragm Seal Filling Station work?

Diaphragm seals are directly mounted to Bourdon Tube gauges, pressure switches and transmitters or connected by a capillary filled with a glycerin or silicon oil liquid.

When pressure is applied to the diaphragm membrane the filling liquid is hydraulically transmitted to the sensing unit.

Contained trapped gases or air in the filling fluid will cause incorrect readings with rising temperatures.

In the degasing process of a filling station a powerful vacuum pump extracts gases and moisture and creates a vacuum in the airspace of the capillary. The filling liquid is drawn into this space by the vacuum and then sealed in.

Schmierer SEA offers a selection of Diaphragm Seal filling liquids for:

- special chemical applications (contamination, hazardous media)

- hygienic and sanitary applications for Food and Pharma

- high temperature and pressure applications

Benefits

Shorter delivery cycles for customized DS applications delivery times of 4 weeks as compared to 3-4 months for orders of branded instruments with customized flanged DS .

Modular setup - a wide range of DS types can be attached locally to the transmitter, switch or gauge from the manufacturer of your choice.

Cost-effective repair of damaged DS in pressure devices savings up to 50% by replacing the DS instead of buying a new transmitter.

Reduced down times of machines and plants due to DS failure.