We want to invite you to visit us at the upcoming AsiaWater 2022 exhibition.

AsiaWater Exhibition

AsiaWater Exhibition

KL Convention Centre

7 - 9 Dec 2022

Schmierer SEA Instrumentation

Hall 1 Booth 111

Bopp & Reuter Filling and Dosing Solutions for water-based media in the Beverage, Chemical and Pharmaceutical Industry:

- shortest filling time: < 0.1 second

- highest measuring accuracy: 0.01%

- lowest conductivity: >1µS/cm

Complete systems with flow meter, batch controller, valves and nozzles and flow computing operator terminal.

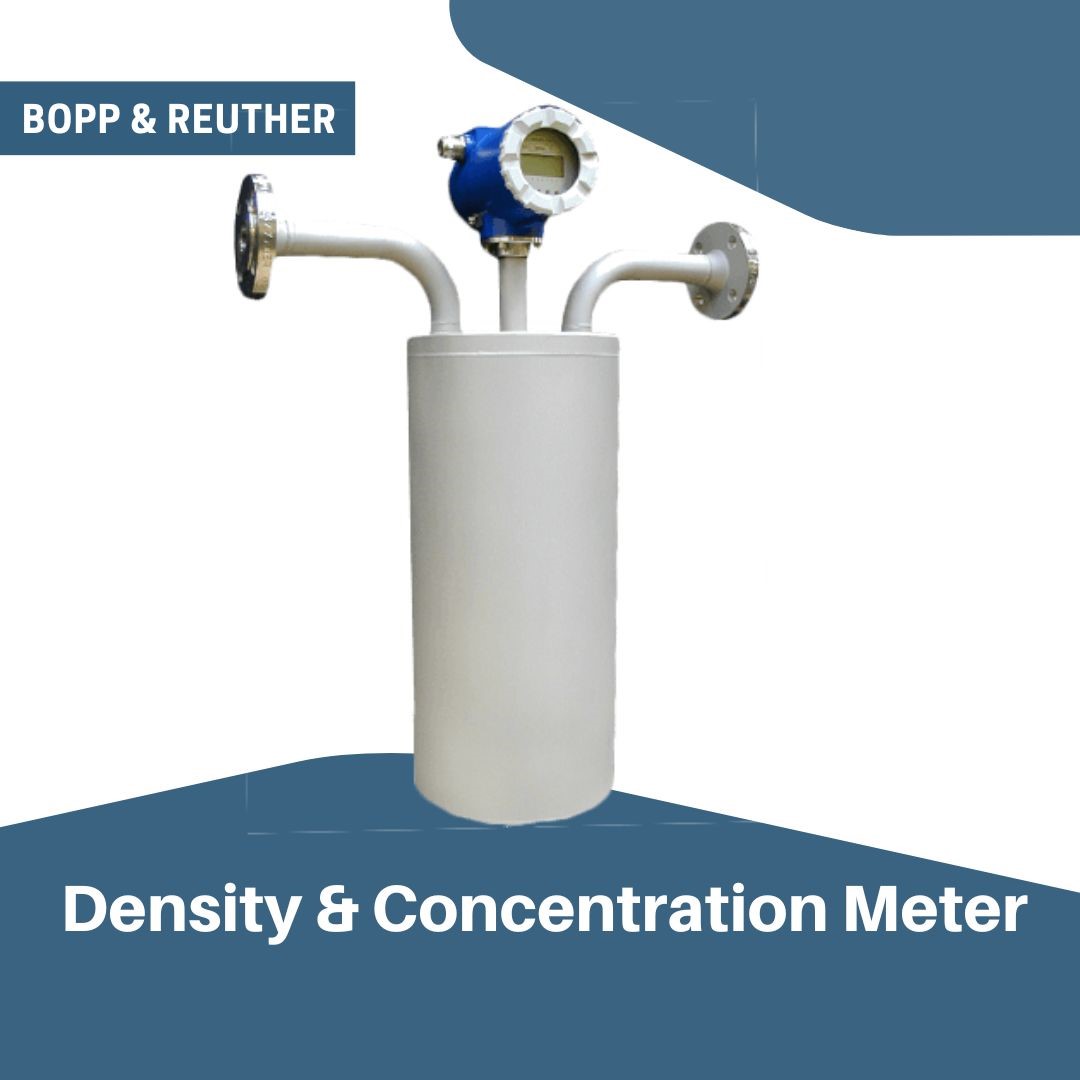

The DIMF liquid density meter from Bopp & Reuther is used for continuous measurement of the density/concentration of liquids or liquid mixtures:

The DIMF liquid density meter from Bopp & Reuther is used for continuous measurement of the density/concentration of liquids or liquid mixtures:

- for hydrocarbons, highly aggressive chemicals, beverages, pastes, foams

- high accuracy (up to 0.01%) - custody transfer - long term stability

- tuning fork principle - robust design - maintenance free

- 400 point correction table for customized parameterization

- Output signals scalable for density and concentration, HART

- Ex protection: flameproof or intrinsically safe

The DIMF liquid density meter from Bopp & Reuther is used for continuous measurement of the density/concentration of liquids or liquid mixtures

The DIMF liquid density meter from Bopp & Reuther is used for continuous measurement of the density/concentration of liquids or liquid mixtures

- acids and bases (hydrochloric/sulphuric/nitric acid, sodium hydroxide, aromatic chlorine solution, ammonia, urea, chlorine, caustic soda,…)

- alcohol and solvents (ethanol, methanol, DMAC, methyl butanol, aceton, glycol, adblue, anti-freeze…)

- solids in liquids (porcelain, ketchup, fat in milk, sugar/Brix, water/starch, tartaric acid…)

- Density measurement (hydro carbons, bio fuel, air bubbles in water …)

The common dangers and "killers" of pressure gauges are:

- vibrations

- overpressure

- pulsations, pressure spikes

- high temperature

- aggressive, corrosive, sticky process media

There are solutions to protect the gauges for inaccurate reading and failure.