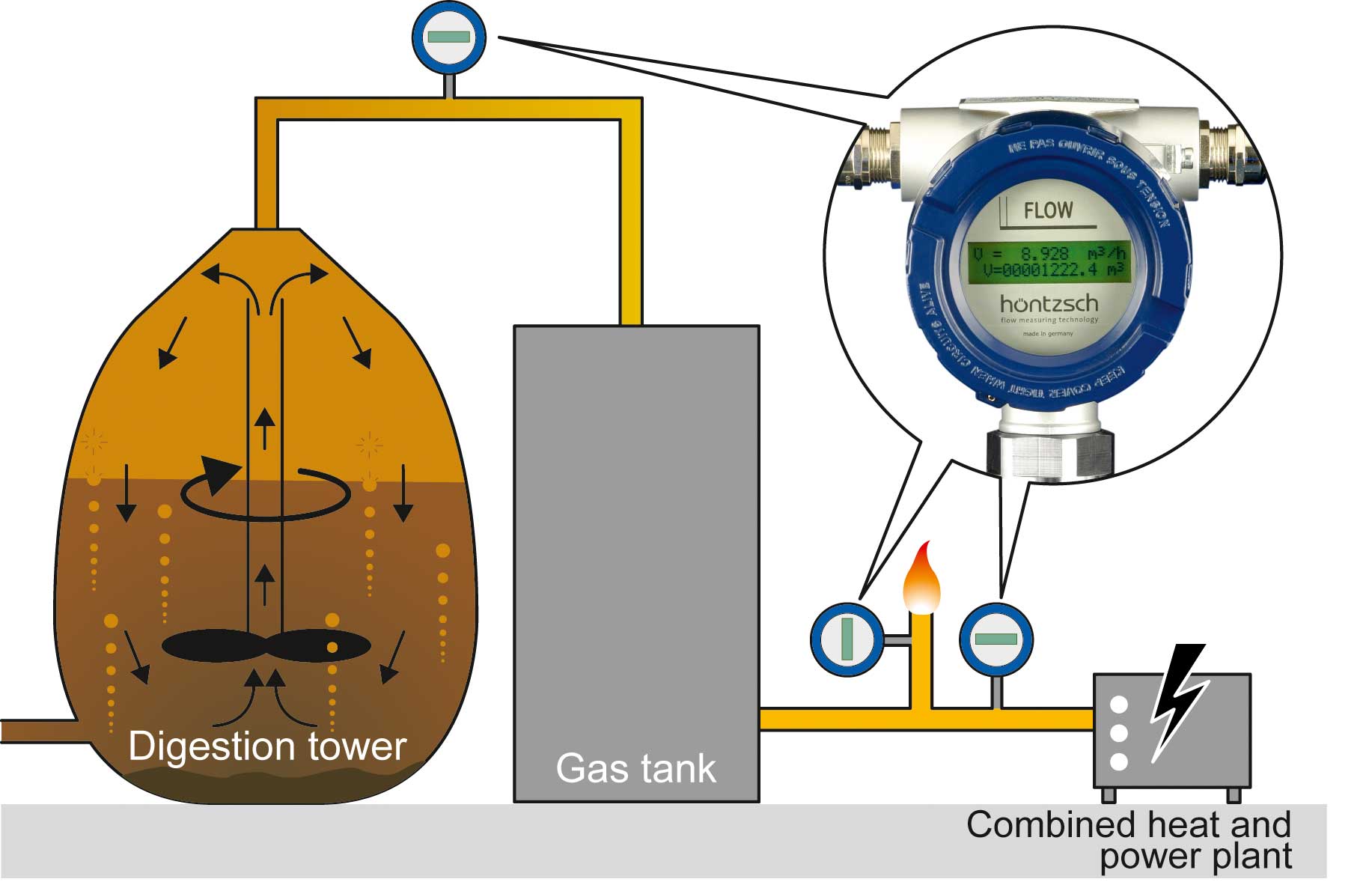

Measuring Points:

- directly after the digester from 0.25 to 2 m s-1 at very low gas pressure of 1–3 mbar only

- in front of CHP stations 8–15 m s-1 at higher gas pressure of 50–100 mbar

- for biomethane at feeding points into natural gas grid 8–10 bar

More in "Collection of Methods for Biogas"

Selection of Flow Meter Instruments

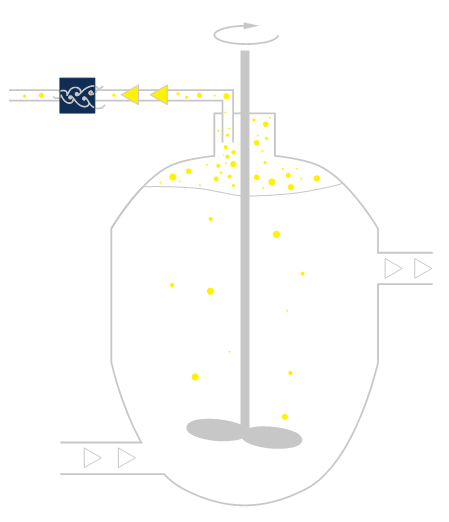

The selection of a suitable flow instrument requires the following parameters: component of biogas, working temperature, working pressure range, pipe size, flow rate (min, normal, max flow).

- Mechanical FM: (Turbine, Orifice, Oscillation): low cost, compact design but large pressure drop, low turn-down ratio, damage through corrosion, clogging, low accuracy with low pressure and flow

- Thermal Mass FM: direct mass flow rate, wide range ratio, no pressure drop but wet gas and different gas compositions lead to measurement errors, re calibration for change of gas mixture

- Vortex FM: reliable measurement for different gas composition and vapor, insertion types but limitations by low pressure and velocity

- Ultrasonic FM: no direct media contact, backflow option, no pressure drop but high damping of acoustic signals by CO2, water condensate, limitations by low pressure and velocity, high end pricing

We recommend the Hoentzsch Vortex Flow Instruments for biogas with corrosive, wet, particle laden and changing gas compositions with Ex approval for hazardous areas. The ultrasonic vortices scanning technology of Hoentzsch vortex sensors with no moving parts allows a low flow velocity range of 0.5m/s (up to 40 m/s) with very low pressure. The insertion type mounting allows easy exchange and cleaning.

Ex 2 gas applications: VA40 ZG7 EX zone 2

Ex 1 gas applications: VA40 ZG8 EX-D zone 0/1 with explosion house proofing