The bypass flow meter operates on the differential-pressure-bypass method. A ring with an orifice plate is installed in the pipeline between flanges. The measuring orifice leads to a constriction and causes a differential pressure. As compensation a volume flow occurs in the bypass which is displayed by a variable area flow meter. This partial flow is proportional to the flow rate in the main pipeline.The unimpeded, straight tube length has to be 6DN before and 4 DN behind the mounting position. The partial flow can be turned on and off, as required, by installing two ball valves in the bypass line..

Hazardous areas are defined are areas with a risk of explosion caused by flammable gases, combustible vapours, dust or fibre.

Hazardous areas are defined are areas with a risk of explosion caused by flammable gases, combustible vapours, dust or fibre.

The term explosion proof protection means that the enclosure (housing) contains the ignition and explosion. The housing material is usually made from cast iron or aluminum. Explosion proof is often used synonymously to flameproof.

Intrinsically safe means that the electronics or wiring are constructed in a way that they limit the energy in the circuit in order to prevent sparks causing ignition. Read more on classes, zones and areas.

Solutions and warranty claims for hazardous areas require the testing and certification of the complete temperature unit (sensor and housing) and not just the individual components.

Solutions and warranty claims for hazardous areas require the testing and certification of the complete temperature unit (sensor and housing) and not just the individual components.

Limatherm offers certified temperature solutions for complete temperature units in flammable/explosion proof and intrinsically safe areas.

Ensim ELG magnetic by-pass level indicators measure the liquid level by a float sensor with a magnet that turns the flaps on an indicating rail (top, bottom or side assembly).

Ensim ELG magnetic by-pass level indicators measure the liquid level by a float sensor with a magnet that turns the flaps on an indicating rail (top, bottom or side assembly).

- clear visual monitoring and control

- easy installation and maintenance

- No electrical power needed.

- Versions for high pressure (100 bar), temperature (350°C), aggressive media (PTFE lining)

- Different transmitter and limit switch alarm options

As Regional Business Partner, Schmierer SEA has been successfully introducing Kirchner Flow Meter Instruments to Applications in the Water, Waste Water, Palm Oil and Chemical Industries. The know-how of Kirchner specialists competence, experience and years of expertise are the foundations of the Kirchner success story.

As Regional Business Partner, Schmierer SEA has been successfully introducing Kirchner Flow Meter Instruments to Applications in the Water, Waste Water, Palm Oil and Chemical Industries. The know-how of Kirchner specialists competence, experience and years of expertise are the foundations of the Kirchner success story.

- Wide range of products

- Specialized product how know with years of experience and expertise

- Customized solutions

- Certified quality Management, (PED, IECEx/ATEX, VDS)

- Short and reliable delivery cycles

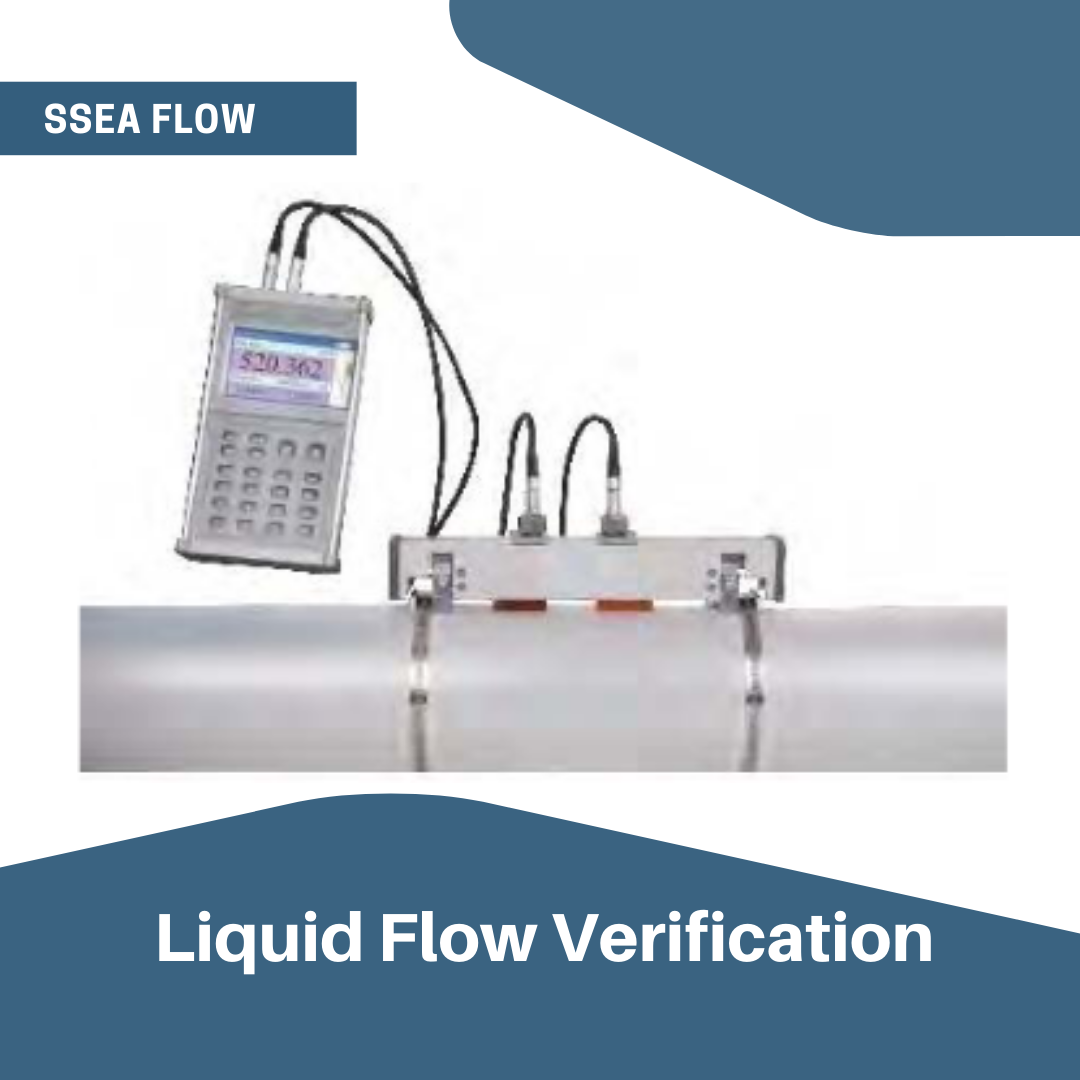

How to verify a mechanical or electro-magnetic flowmeter for liquids without interrupting the flow process, dismantling the meter and sending it to a calibration lab? Inaccurate or wrong readings may cause higher expenses in raw material, losses in production and even endanger your staff and environment. We suggest to install a portable ultrasonic clamp-on flow meter for flow verification.

How to verify a mechanical or electro-magnetic flowmeter for liquids without interrupting the flow process, dismantling the meter and sending it to a calibration lab? Inaccurate or wrong readings may cause higher expenses in raw material, losses in production and even endanger your staff and environment. We suggest to install a portable ultrasonic clamp-on flow meter for flow verification.