The standard solution of filling gauges with glycerin oil achieves a damping effect but requires regular refilling maintenance. Oil leakage due to a mechanical gauge damage can cause potential contamination of the process media. In addition hot and humid climatic conditions can lead to a blurry display glass window.

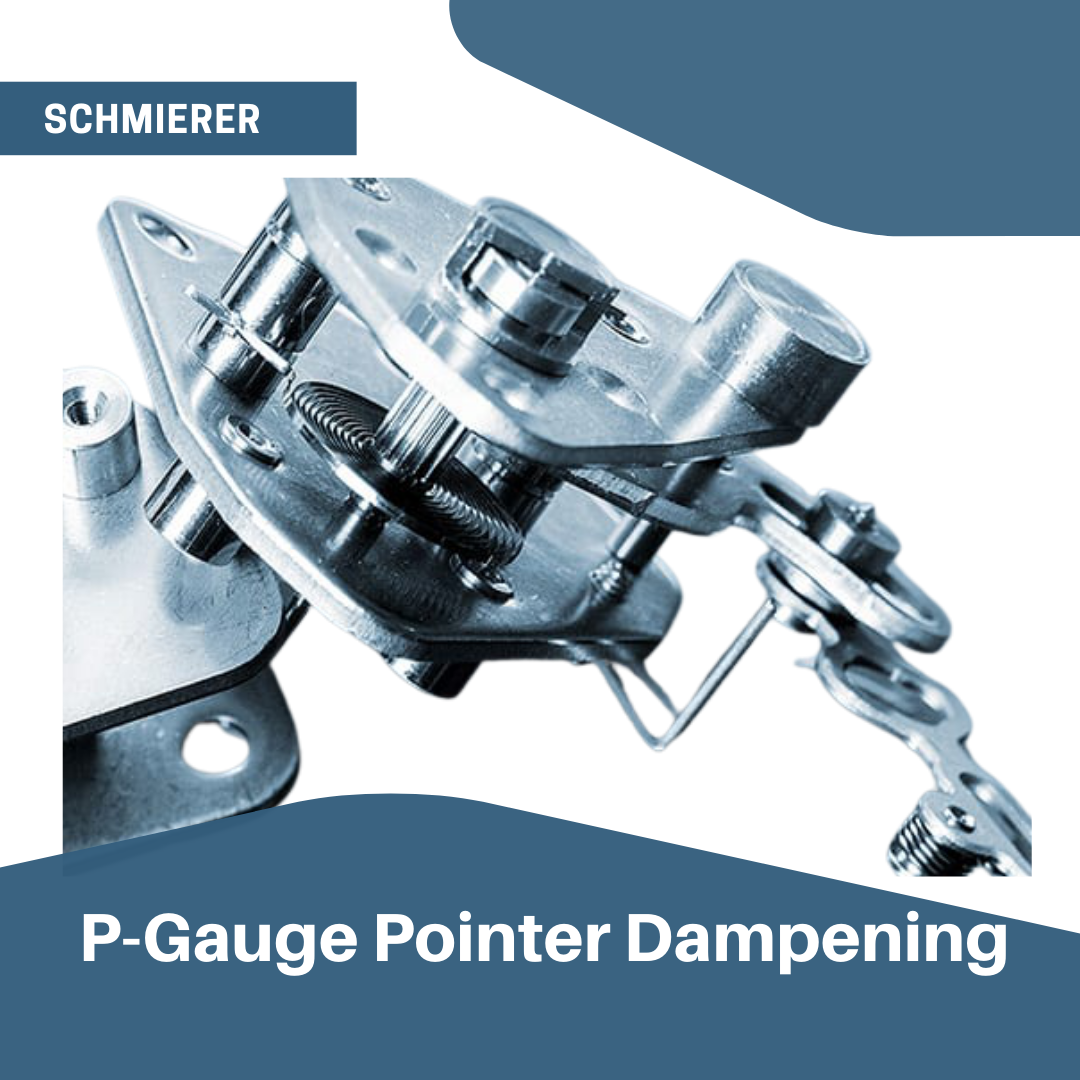

Since 1974 Schmierer has developed, field tested and improved a new type of pointer dampening for pressure gauges. Resulting from all these tests and experiences, the construction of a movement, which is equipped with a damped axle and the specific construction of the push-rod was started. It would go on to be built in larger numbers – known under the Schmierer brand MANODAMP®.

Advantages

MANODAMP® Gauges have significant advantages to the “classical” liquid-filled gauge cases:

- No oil leakage problem - no contamination risk of process media

- No blurry gauge glass window in hot and humid climates

- No oil refilling maintenance required

- Easy maintenance for needle zero readjustment or change of movement parts

- Longer service life of gauges in rough environments

- Modern up to date construction fulfills the technical and hygienic requirements of chemical, petrochemical, food and pharmaceutical industries

- Experience with successful long service life in customer plants

We can deliver pointer dampening with Manodamp® movements in Schmierer Bourdon Tube and Diaphragm pressure gauges with 100 mm or 160 mm diameter with a pressure above 2.5 bar.