Generating compressed air is highly energy costly. Companies are constantly trying to reduce consumption. Consumption measurement ist also necessary for a possible DIN EN ISO 50001 certification for energy management.

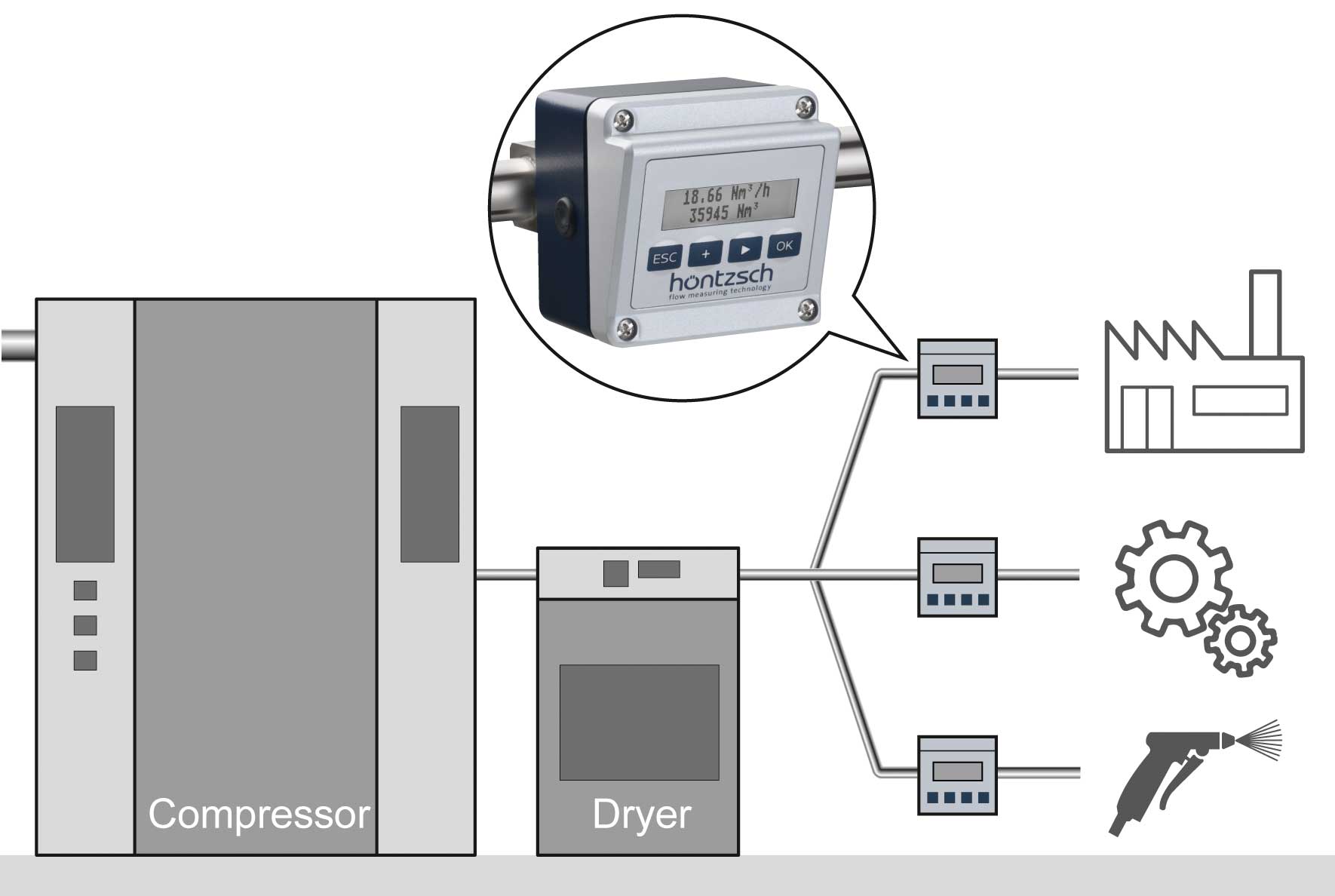

Therefore measurement of compressed air consumption has been a standard procedure in the industry for years now. The source (the compressor), certain parts of the company from production halls to individual production cells need to be monitored.

Portable temporary measurements are also required. That way consumption can be measured at a specific point of the compressed air net and certain actions can be taken. The goal is to increase energy efficiency and therefore optimise the company’s ecobalance.

Flow rate of compressed air can vary a lot depending on the location of measuring. Applied sensors should therefore have a great turndown ratio.

Flow rates of compressed air can vary widely depending on the location. Flow measurement sensors therefore need to have a great turndown ratio. Hoentzsch thermal probes for compressed air, N2, CH4 pipes are suitable for portable handheld or fixed evaluation measurement and display of flow velocity, flow rate, mass flow, volume and mass.

Process data

- Measuring task: standard flow rate; mass flow rate

- Measuring point: in compressed air pipe

- Measuring range: 0.04 to 20,000 Nm³/h

- Process pressure:16 bar

- Process environment: optional up to ATEX zone 0

- The probe pressure loss is negligible

Measuring standard flow rate in compressed air pipes

Measuring task:

Standard flow rate; mass flow rate

Measuring point

In compressed air pipe

Measuring range:

0.04 to 20,000 Nm³/h

Maximum working pressure:

16 bar

Process environment

Optionally up to zone 0

Your advantage

Many areas of application

Very high turndown ratio of 1:1000

Efficient

Negligible pressure loss compared to other measuring methods

Safe

Versions for ATEX zone 1 and 0 are available

Recommended products

Thermal probe TA 10 ZG2d

Standard compact sensor

To the product Product data sheet

Thermal measuring tube TA Di

Standard – with an integrated transducer

Does compressed air have to be so expensive?

No way!

Compressed air is an expensive energy source and should therefore be used responsibly. To recognise possible savings, measuring instruments for precise measurement of compressed air consumption is required, improving energy balance and saving costs. Compressed air is also needed on a large scale in municipal sewage treatment plants for their aeration basins. The demand represents a significant if not the largest share in the energy consumption of the municipality providing great potential for savings. Compressed air and electricity consumption can be localized and reduced through an exact consumption measurement. This is an essential contribution to the company’s energy management and can be part of the certification.

What advantages do thermal flow sensors provide for energy management?

Höntzsch’s thermal flow sensor TA allows direct gas mass flow rate measurement without additionally requiring pressure and temeprature sensors. It is very small and therefore not being a big obstruction in the pipeline making the pressure loss quite negligible. The small time constant of 1 s enables accurate measurement with high temporal resolution. Our thermal sensor TA is suited for pipelines with an inside diameter starting at 8 mm.

Additionally to compressed air other gases such as propane, butane or hydrogen can be measured as well. They are also very valuable gases, their consumption a cost relevant factor and are important for energy management.