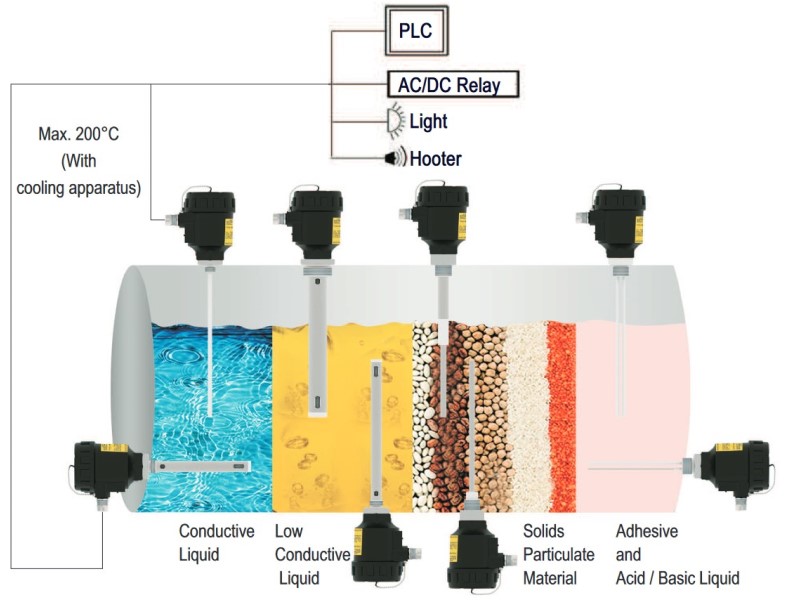

Capacitance Level sensors operate on the change of electrical capacity (capacitance) for a capacitor formed by two conductive plates (the sensor, vessel wall or outer shell of the probe) and the dielectric material which is proportional to the tank level.

Conductive liquids, (usually water based, low dielectric constant) measure the capacitance between the sensor probe and the tank wall. They are independent on the tank geometry and dielectric constant of the media, (insulated probe).

Non-conductive liquids (usually oils and solvents, high dielectric constant) form an additional capacitor. They measure the capacitance between the inner rod and an outer shell immersed in the liquid). The measurement depends on the dielectric constant and tank geometry, (coaxial probe).

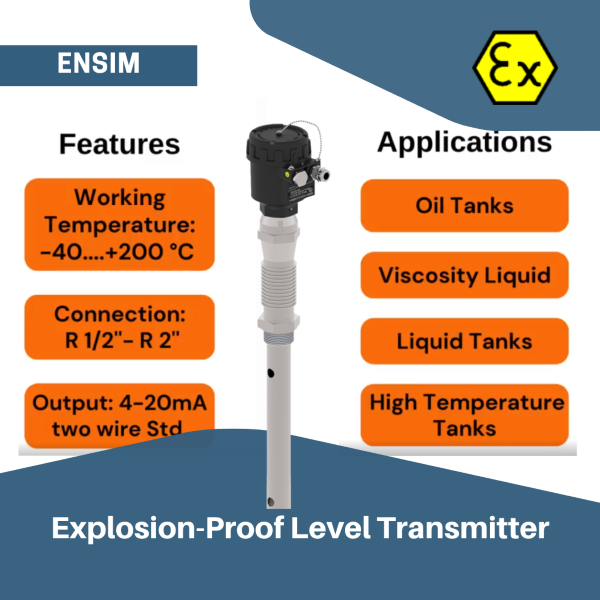

Advantages:

- no moving parts

- high pressure and temperature resistant design

- modular structure with easy assembly

- not affected by foam, liquid splashes

- not affected by vibration, robust mechanical structure

- zero span adjustment is easy

- measurement along whole sensor

- operation with reverse assembly

Industrial Applications:

- Liquid tanks, food machines, cooling liquid tanks, shipping, glycol tanks, brine, waste water tanks.

- Oil tanks, CO2 liquid tanks, high temperature tanks, non-conductive liquids.

- Grain stores, cement, sand feed, flour, milk powder, organic and plastic granule.

- Sticky hot and high viscosity liquid, acid and chemical liquids.