Syphons and Cooling Towers, Diaphragm Seals

Common pressure gauges can tolerate a process temperature around 100°C. Cooling towers or syphons protect instruments from direct contact with high temperature process fluids or vapors filled with condensation fluids.They are mounted between the process pipe/tank and instrument.

|

|

|

||

| Cooling towers are made of stainless steel. Perforated and Fin type towers are used for up to 220°C, capillary types for up to 150°C. | Syphons come in pigtail, coil or "U" shape types and protect upto 400°C and 160 bar. They can be TIG (Tungsten Inert Gas) welded, hydro tested and made with seemless pipes. | Diaphragm seals protect the pressure instrument from highly corrosive, aggressive, viscous or clogging (particle laden) process media, high temperature or pressure or to protect high purity process media from contamination. |

Overload Protector, Pulsation Dampener, Movement Stabilizer

|

|

|

|

||

| the Overload Protector protects the instrument from over pressure exceeding the specified pressure range by sudden & excessive pressure fluctuation from surges or spikes. Models range from 200 mbar up to 400 bar. | The Pulsation Dampener "Snubber" protects pressure instruments from sudden pressure changes and fluctuations for Hydraulic Machines, Compressors, Process Plants, Clean air, Gases & Non Crystallized liquids. Working pressure up to 390 bar. | The Manodamp® mechanical stabilizer feature is built into the pressure gauge movement (with the attached needle pointer) to protect the instrument from vibrations or sudden pressure changes within the designed pressure range and stabilize the needle for easy reading. |

Gauge Cocks, Valves, Manifolds

|

|

|

||

| Gauge Cocks are used to prevent media contamination or lubricant wash out for hydraulic machines, compressors, clean air, gases, non-crystallizing liquids, optionally with air vent hole | Needle Valves are used for instrument line throttling or bubble tight complete instrument shut off, instrument isolation, draining valve for high pressure instrument lines (gas and some liquids, upto 400 bar). |

Manifolds are designed as miniature valve for remote mounting, (isolation, calibration, purging). 2 Valve manifolds for static pressure, 3 Valve manifolds for DP pressure applications. |

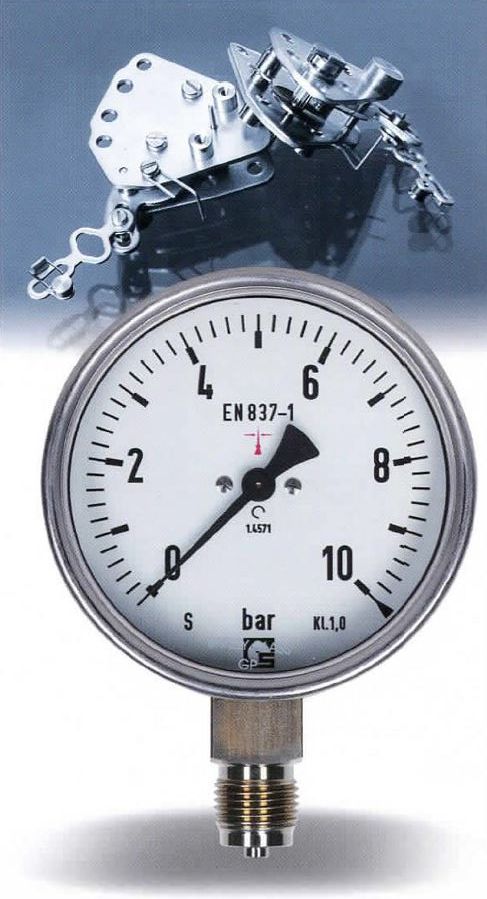

Pressure Gauges need to be protected from high temperature, vibrations, sudden pressure changes, overpressure, corrosive, viscous or particle laden process media. Valves and Manifolds assure an easy shut of or remote mounting. Here is a description of the most common Pressure Gauge assessories.

Pressure Gauges need to be protected from high temperature, vibrations, sudden pressure changes, overpressure, corrosive, viscous or particle laden process media. Valves and Manifolds assure an easy shut of or remote mounting. Here is a description of the most common Pressure Gauge assessories.