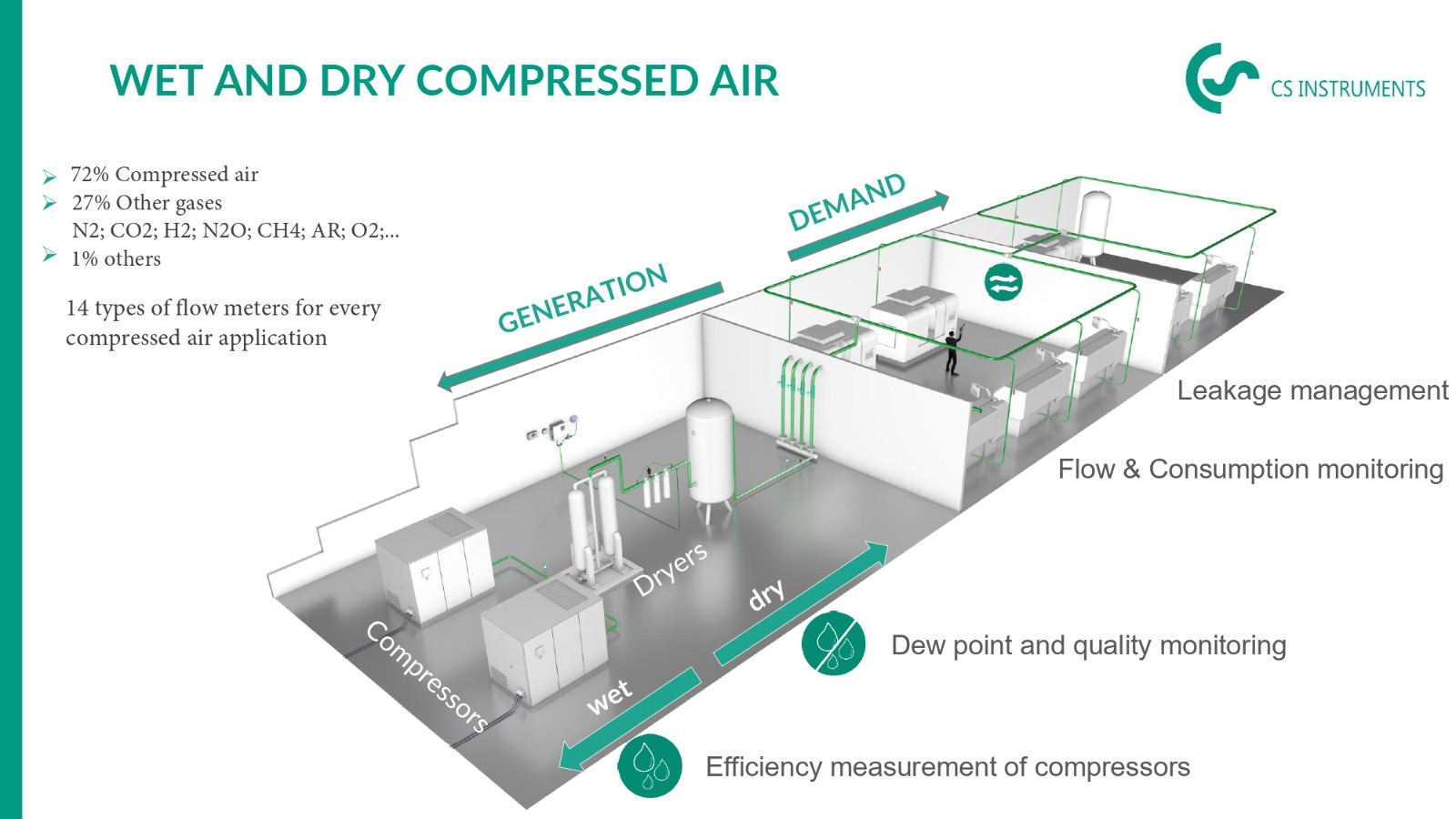

Wet and Dry Compressed Air

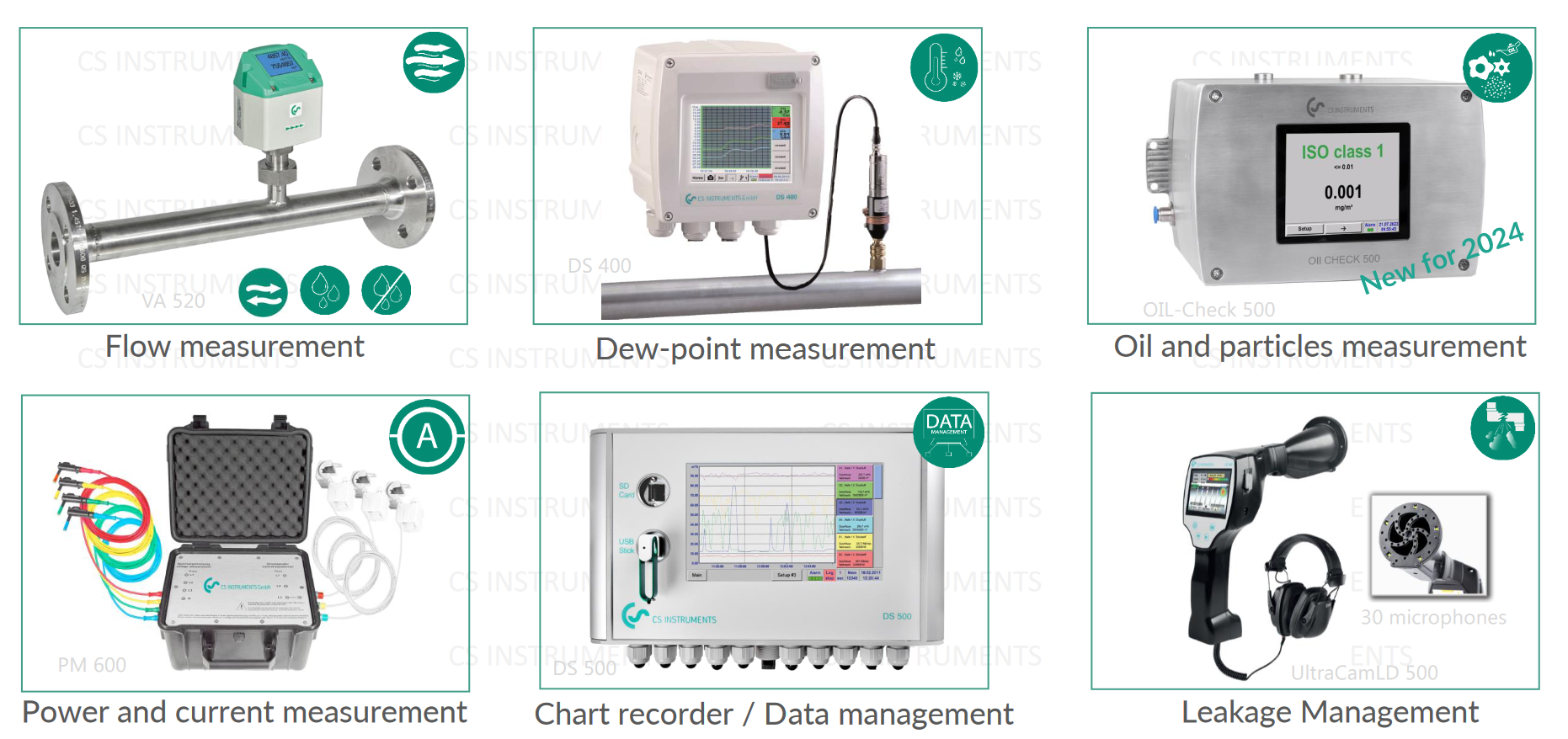

Compressor Efficiency Measurement

- compressor energy consumption contributes to 80% of the compressed air cost

- monitoring power input, flow output, ratio, energy cost

- status and efficiency of compressors

- cost saving and minimizing the environmental footprint

Quality Monitoring of Compressed Air

- dew point, residual humidity: monitoring of compressed air dryers and filters

to prevent corrosion, bacteria growth, oil film clogging of pipes - residual oil vapor: monitoring hydro carbon content in compressed air

- particle counter: monitoring of concentration of solid particles in compressed air

Flow and Consumption Monitoring in Dry Compressed Air

- monitoring of factory consumption, department consumption

- leakage rates of different areas

- evaluation software

- consumption of point of use level

Leak Detection

- ultrasonic leak detector cameras

- locating and quantifying leakages, l/min, cost

- leak data evaluation software and reports

- reducing energy loss and production cost