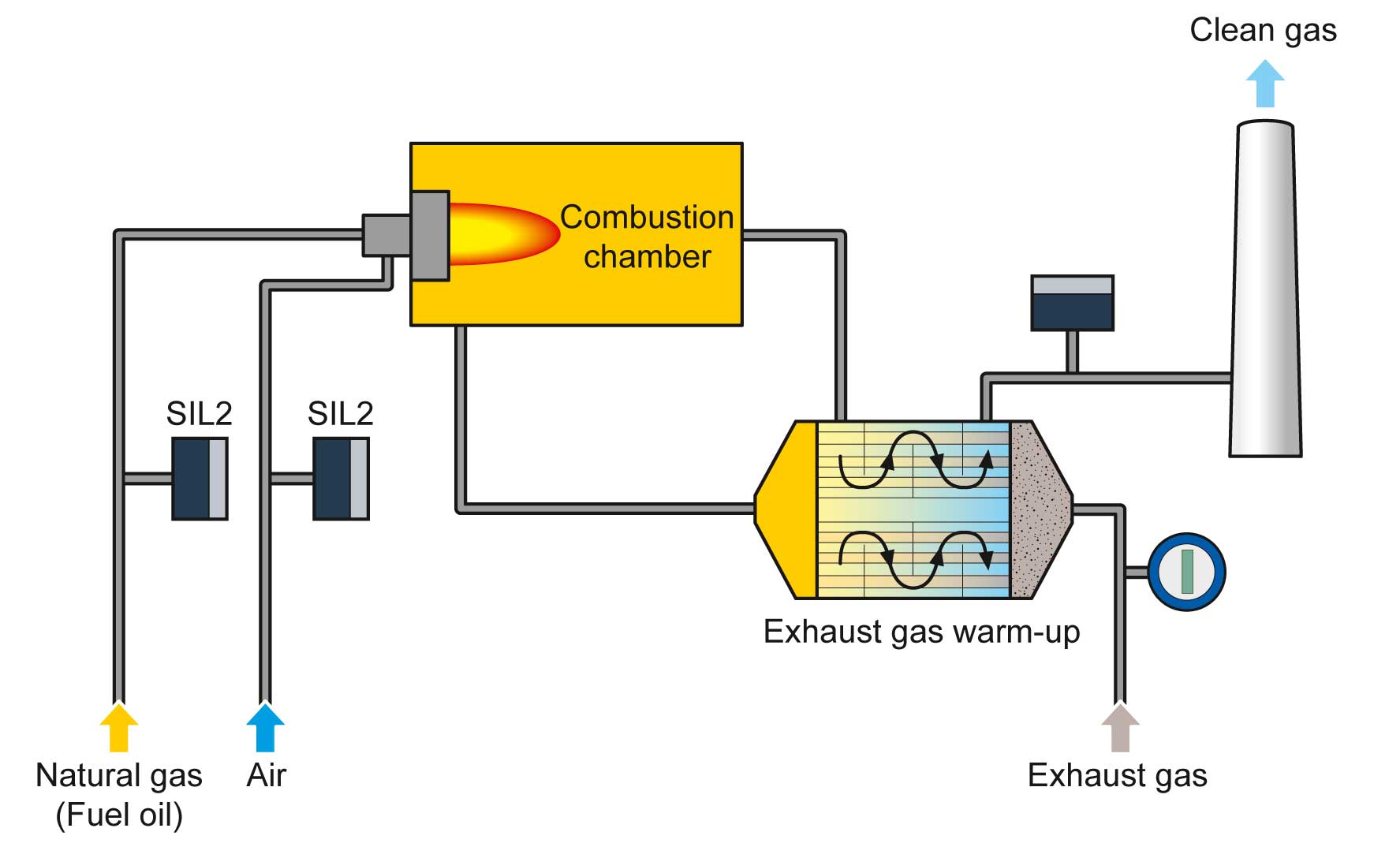

Thermal or thermal regenerative post-combustion is the process of cleaning industrial exhaust gases. Contaminated air, explosive process gases, flare and waste gases are lead to a combustion chamber and burned in temperatures between 700 °C and 1,200°C.The Höntzsch Vortex sensor with ATEX and SIL certification measure the flow rate of inflowing, solvent-containing exhaust air to manage the high energy consumption in combustion. They are robust (no moving parts) with longevity and minimal maintenance.

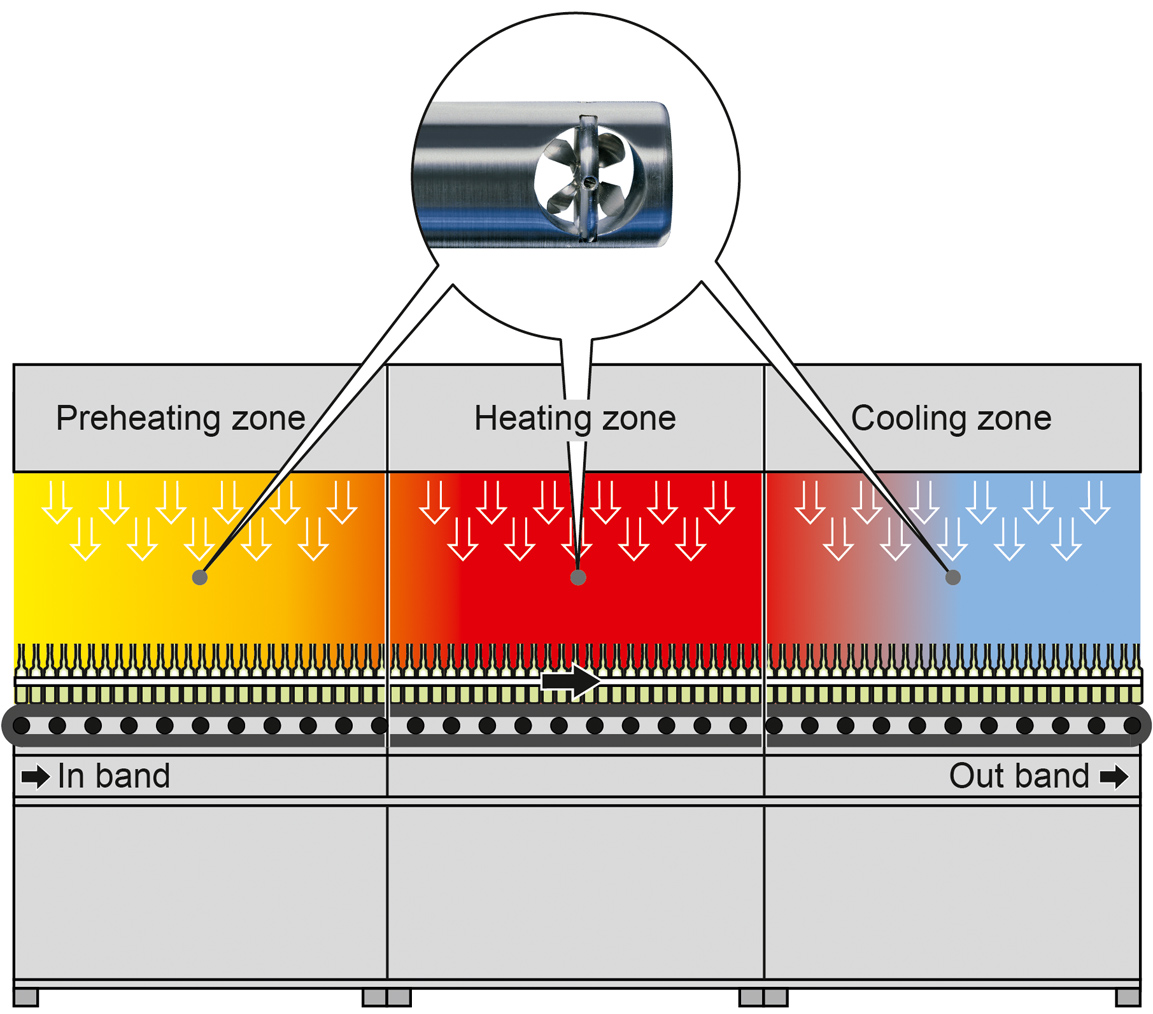

In sterilizing tunnels hot air flows through the so called HEPA-filter down into the heating zone. There, sterilizing hot air with a very low flow velocity is blown down to the glas containers and monitored with Hoentzsch Vane Wheel Flowsensors.

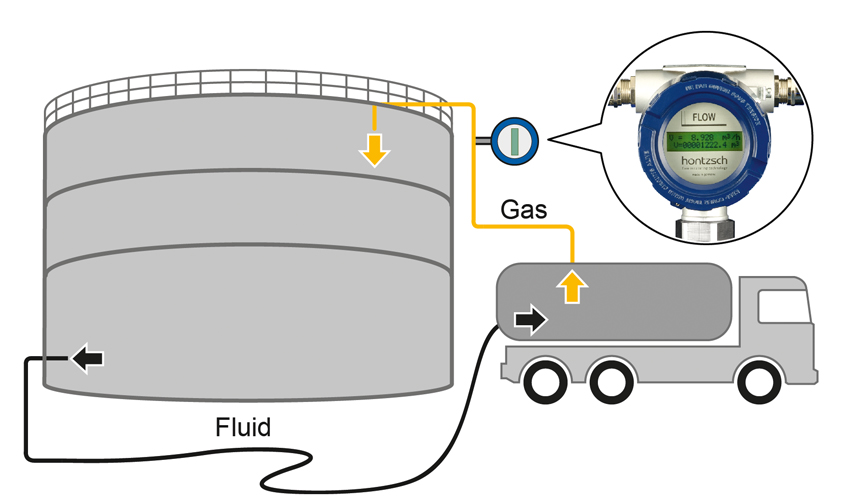

Measuring flow rate in the recovery gas pipe during gas recovery

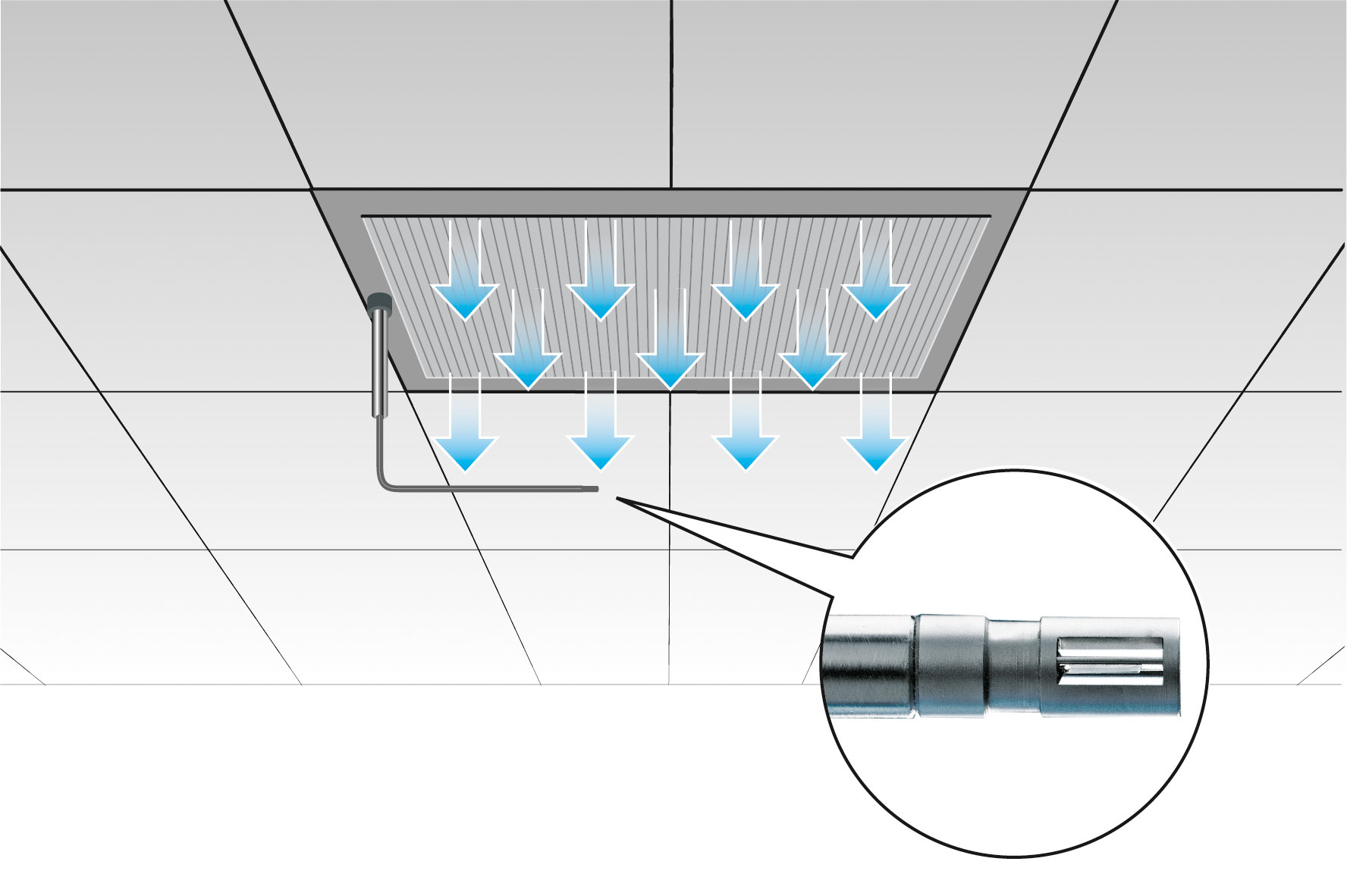

Flow velocity for process regulation for paint booth, clean rooms, semiconductor and filling and packaging applications.

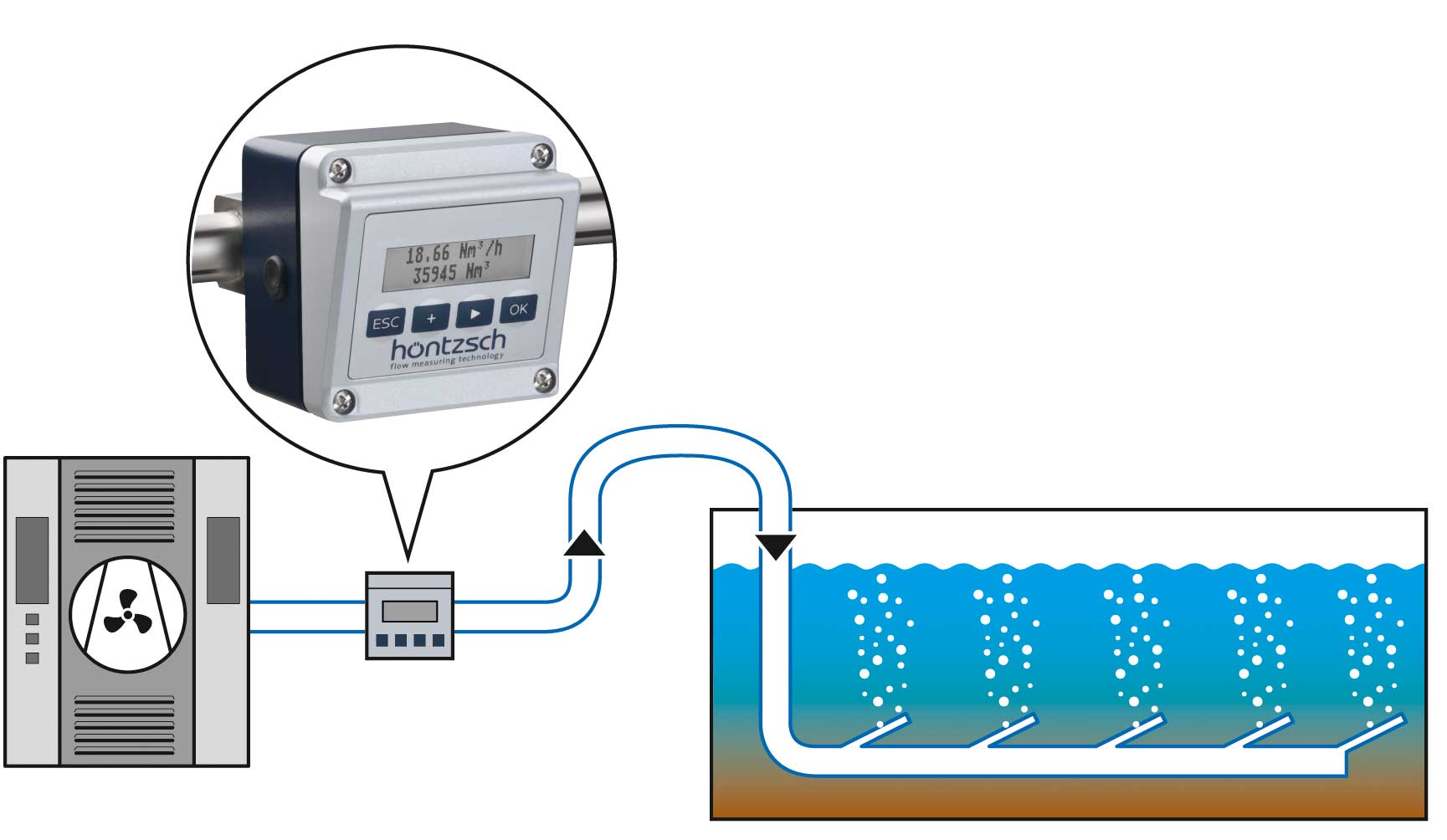

Many municipal sewage plants apply the activated sludge process where sludge aeration air is being pumped into aeration basins, speeding up the degradation process. To increase the plant’s energy efficiency flow velocity should be measured in order to calculate (mass) flow rate.

Many municipal sewage plants apply the activated sludge process where sludge aeration air is being pumped into aeration basins, speeding up the degradation process. To increase the plant’s energy efficiency flow velocity should be measured in order to calculate (mass) flow rate.