How to fix your compressed air leaks

Start saving money by reducing the energy consumption of your compressed air system by repairing your compressed air leaks.

Multiuser System - Advantages of the Cloud Solution:

- No more installation required – login with username and password via browser, so you have access to your data anytime and anywhere and your IT department is not needed to install the software on your computer or to perform updates.

- One central database - Each user always accesses the current database, additionally the data security is higher due to automatic data backups

- Multiuser system - For each user you can individually define which data he/she has access to, and which functions he/she is allowed to use

Which compressed air flow meter should be used at which point?

1. Flow meter types (in line, insertion, end user)

2. Free air delivery with differential pressure measurement for “wet air” (VD 500)

3. Thermal flow meters for consumption measurement (VA5XX)

4. Which benefits does a sophisticated flow measurement system offer?

5. Explanation of the measuring points

Compressed Air Monitoring with the DS50

From recording of the measured data, indication on a big colour screen, alerting, storage up to remote read-out via webserver... this is all possible with DS 500.

- Compressed Air Quality

- Air Pressure

- Dew Point

- Flow Meter

- Temperature

The big difference to ordinary paperless chart recorders reveals in the easy initiation and in the evaluation of the measured data. All sensors are identified directly and powered by DS 500. Everything is matched and tuned.

How to install a compressed air flow meter under pressure?

- Consumption and leakage rate measurement

- Compressed air demand profile

- Easy installation via ½” ball valve

- Usable from ½” to 12”(DN 300)

Locating leaks with the ultrasonic leak detector LD 500

Since 2002 the name CS Instruments has stood for proven and innovative measurement technology for compressed air and gases.

This video illustrates:

- Configuration of the device (parameterization and measuring point)

- Explanation of the user interface

- Localization of a compressed air leakage (real application)

- Storage of the leakage data

- Validation of the leak elimination

Electro-Magnetic Watermeter with high range and low flow measurement

The SSEA Electro-Magnetic Watermeter for large scale water metering systems and water leakage detection. The high range ratio (R250, R400) ensures high precision measurement of low flow (5mm/sec) at night and large flow at peak hours.

The SSEA Electro-Magnetic Watermeter for large scale water metering systems and water leakage detection. The high range ratio (R250, R400) ensures high precision measurement of low flow (5mm/sec) at night and large flow at peak hours.

- high accuracy measurement

- no missing records

- reduced loss of the pipeline network, increased revenues

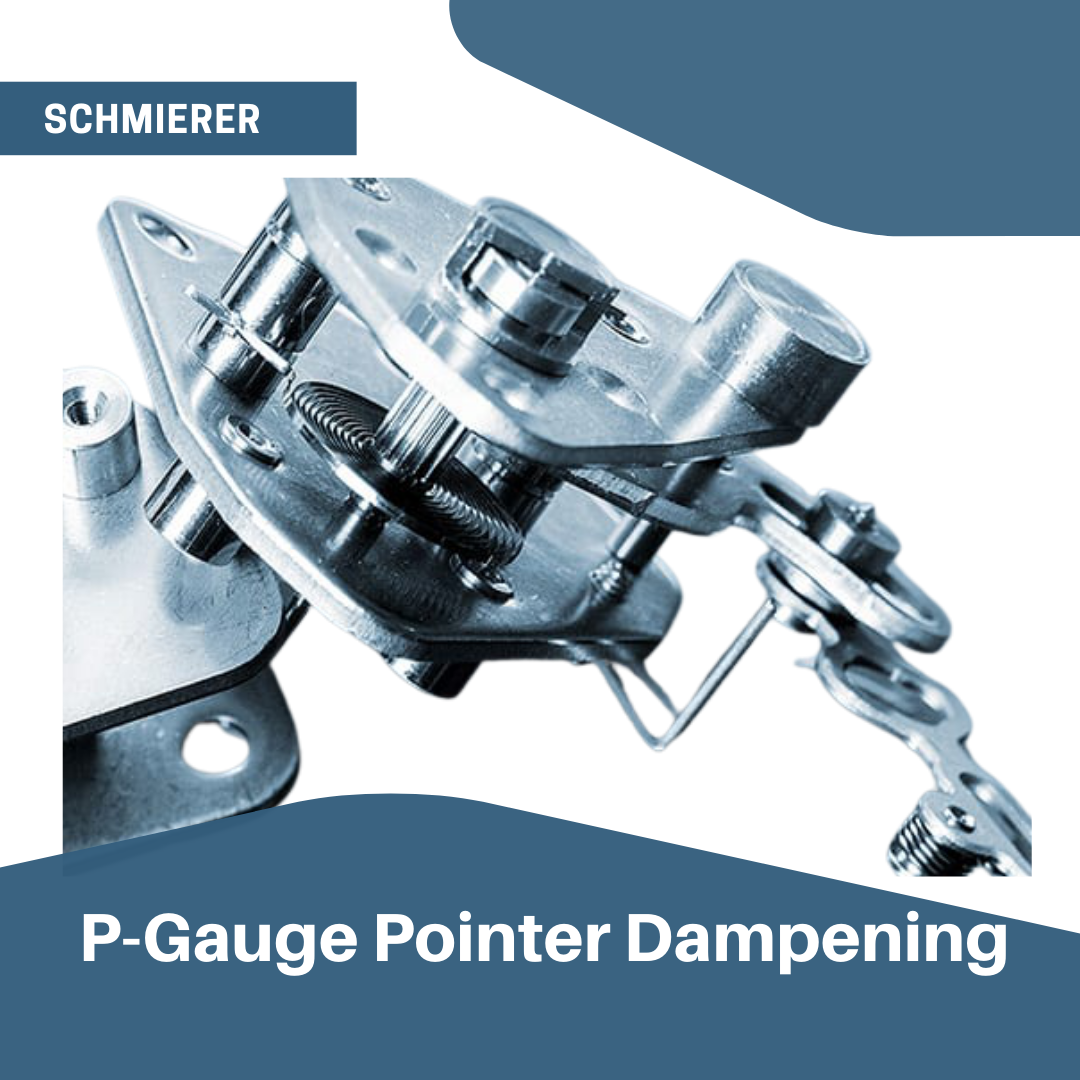

Pressure Gauge Pointer Dampening with Manodamp® Movements

Rough industrial work environments with

- vibrations

- sudden pressure changes or

- high purity demands

require a special protection mechanism for the pressure gauge movement with the needle pointer. The Manodamp® technology offers this solution.

Coriolis Massflow for Pharmaceutical Applications

The pharmaceutical industry is highly regulated and has a need for measurement performance and traceability.

Rheonik sanitary sealless mass flow sensors do not contain any elastomer seals and are available with fully wetted materials traceability.

Rheonik meters offer preferred materials and high performance measurement with a reduction in documentation burden for all sanitary flows.

Coriolis Massflow for Renewable Energies

More and more of our energy comes from renewable clean energy sources like solar, hydro and geothermal. Rheonik Coriolis Massflow Meters play a big role in high performance and efficiency measurement of energy from renewable energy sources such as

- Hydrogen high pressure dispensing

- cryogenic liquid gas

- battery manufacturing

Schmierer Diaphragm Seals

Diaphragm seals are used to protect pressure instruments from corrosive, viscous, clogging or hot process media and safeguard highly hygienic and ultra pure liquids from contamination.The seals and membranes are customized for a variety of applications with different materials, coatings and linings, mounting and connection types.