As Regional Business Partner, Schmierer SEA has been successfully introducing Kirchner Flow Meter Instruments to Applications in the Water, Waste Water, Palm Oil and Chemical Industries. The know-how of Kirchner specialists competence, experience and years of expertise are the foundations of the Kirchner success story.

As Regional Business Partner, Schmierer SEA has been successfully introducing Kirchner Flow Meter Instruments to Applications in the Water, Waste Water, Palm Oil and Chemical Industries. The know-how of Kirchner specialists competence, experience and years of expertise are the foundations of the Kirchner success story.

- Wide range of products

- Specialized product how know with years of experience and expertise

- Customized solutions

- Certified quality Management, (PED, IECEx/ATEX, VDS)

- Short and reliable delivery cycles

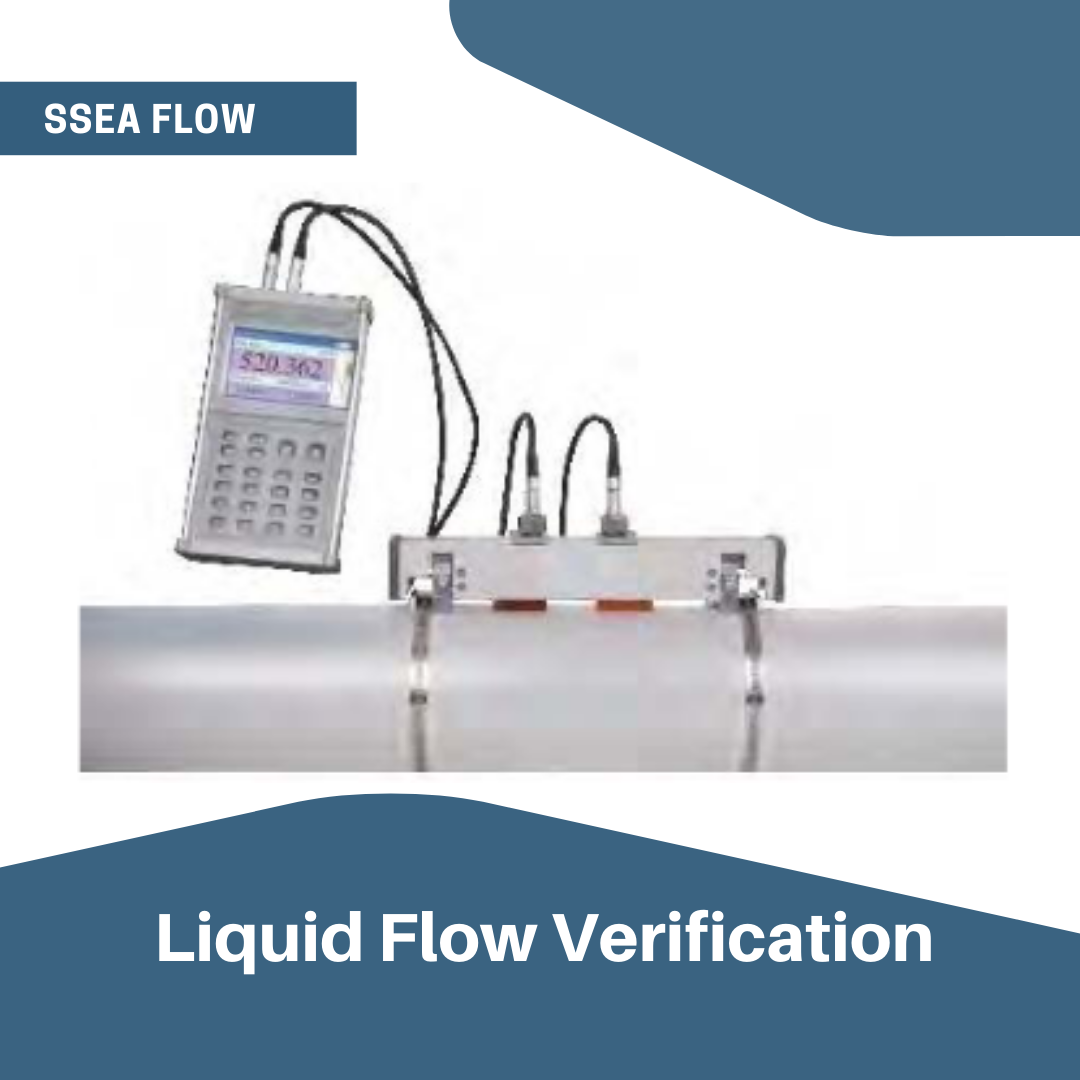

How to verify a mechanical or electro-magnetic flowmeter for liquids without interrupting the flow process, dismantling the meter and sending it to a calibration lab? Inaccurate or wrong readings may cause higher expenses in raw material, losses in production and even endanger your staff and environment. We suggest to install a portable ultrasonic clamp-on flow meter for flow verification.

How to verify a mechanical or electro-magnetic flowmeter for liquids without interrupting the flow process, dismantling the meter and sending it to a calibration lab? Inaccurate or wrong readings may cause higher expenses in raw material, losses in production and even endanger your staff and environment. We suggest to install a portable ultrasonic clamp-on flow meter for flow verification.

to monitor critical values, trigger alarms, start, stop or switch processes:

- available with single, double or triple setpoints

- nominal value can be set from the outside

- inductive contacts for use in ex zones

Centec Germany manufactures a wide range of automated process skids for various applications in the food and beverage industry;

Centec Germany manufactures a wide range of automated process skids for various applications in the food and beverage industry;

- a combined multimixer for deaeration, accurate syrup blending and carbonation suitable for soft drinks

- water treatment and filtration units, etc.

Starting from engineering, assembly, Factory Acceptance Test (FAT), Centec delivers and commissions complete turn-key plants.

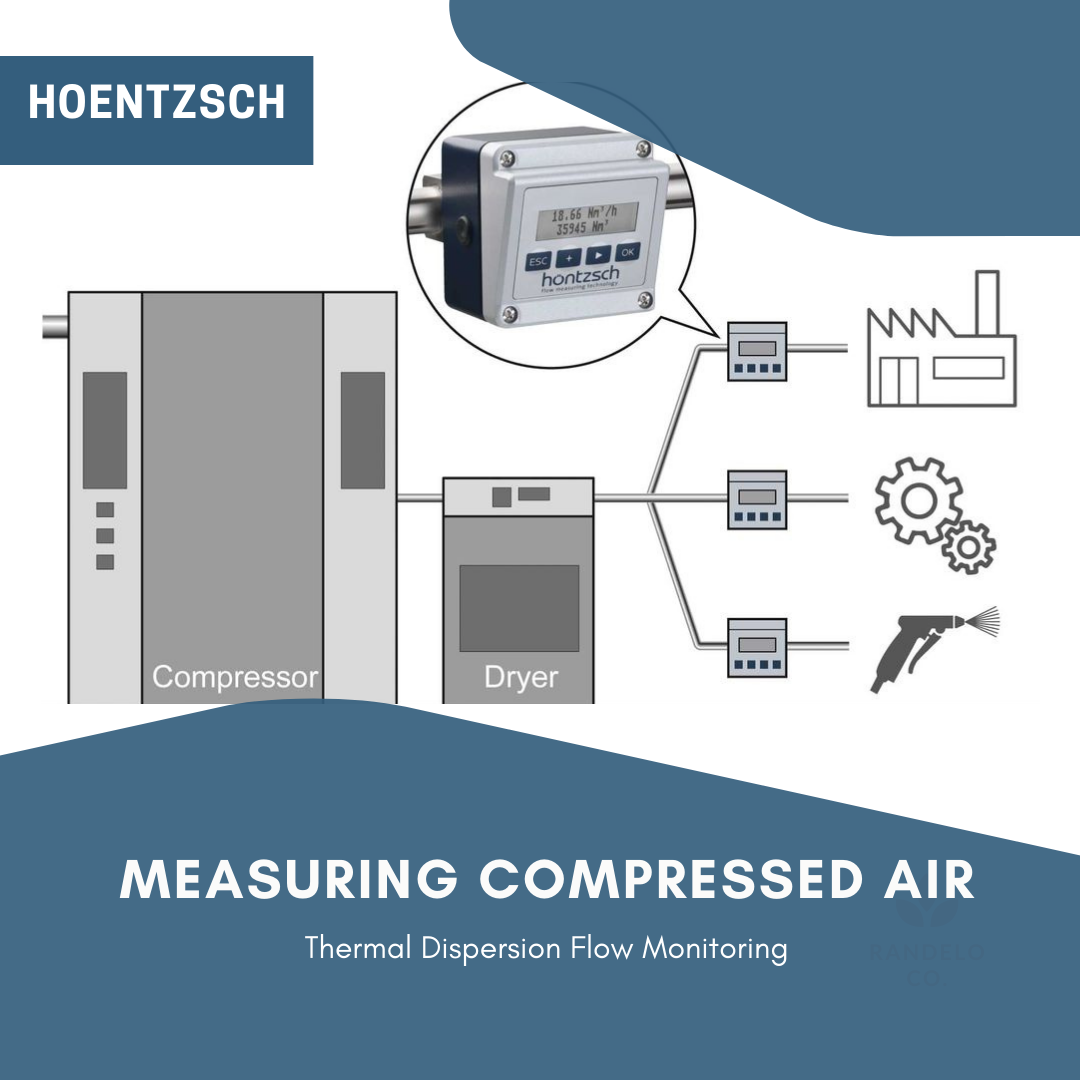

Compressed air is used in the Automotive, Paint spray, Pharma, F&B and many other processing industries. It is energy costly. For energy efficiency it needs to be monitored from the compressor to the production cell/hall. The consumption measurement ist also required for DIN EN ISO 50001 energy management certification.