Application

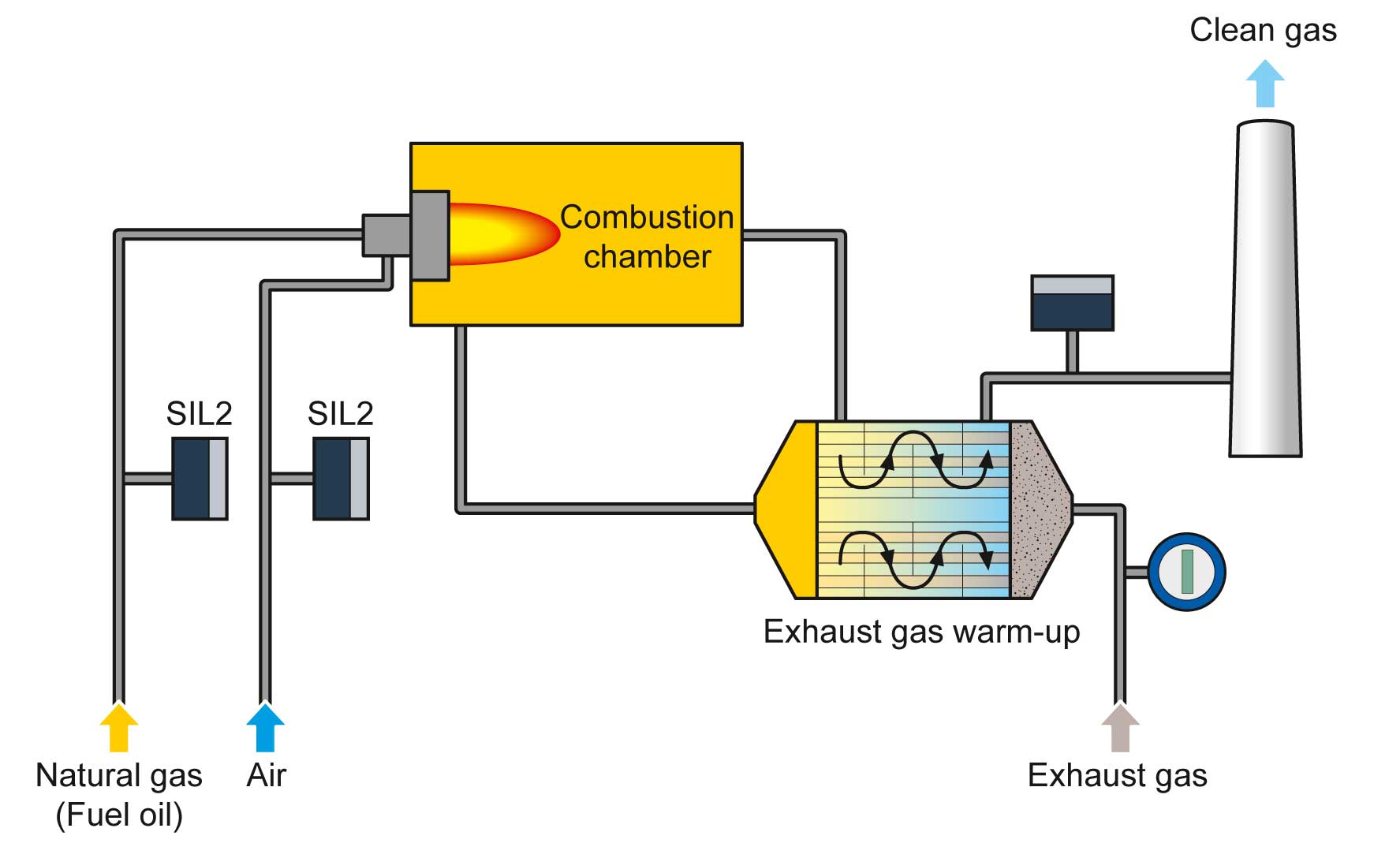

Thermal post-combustion is an exhaust air and exhaust gas cleaning process. Air hygienically it’s an optimal process because exhaust air/exhaust gases except for sulfur, halogen or other thermally non-decomposable foreign substances are turned into the non-hazardous substances water (H2O) or carbon dioxide (CO2). The process is perfectly suited for VOC laden gases starting at 1g/Nm³ at a VOC precipitator efficiency over 99.8 %. That way required limit values can be adhered to.

Fast start and stop allow the use under highly fluctuating process conditions.

Special flow sensors can measure inflow of exhaust gases to the post-combustion plant and therefore regulate the process, guaranteeing optimal combustion.

Process data

- Measuring points: supply point of exhaust air, supply point of natural gas, supply of air in TNV (RTO), exhaust air after the TNV

- Measuring range: typically 5 to 15 m/s

- Process pressure: slight underpressure, overpressure

- Process environment: typically ATEX zone 2, sometimes SIL 2 required

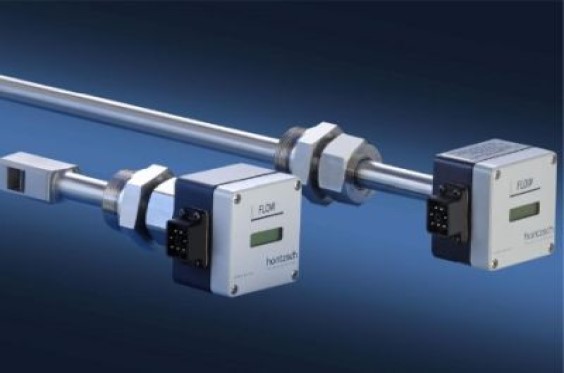

Recommended Hoentzsch Products

Vortex probe VA40…ZG7: standard compact unit, variable insertion depth

Handheld unit Flowtherm ex: multifunctional handheld with datalogger - for the use in explosive atmospheres