Coriolis Massflow Paint and Coating Applications

Paint and coating applications require metering capable of handling thick, “sticky” and often abrasive materials. Meters must additionally be able to withstand pump pulsations at often high line pressures due to the viscous nature of the flows, all the while providing measurement to the highest degree of accuracy.

With high pressure thick wall tubes that resist abrasion and no internal splitters to clog or block, Rheonik meters provide reliable, high accuracy flow measurement for all paints, coatings and adhesives.

Additive Dosing Process System

The additive dosing system ADoS is used for dosing of ingredients such as vitamins, flavours and colours directly into the main product stream. The compact skid provides a high degree of flexibility for the production of different products.

The additive dosing system ADoS is used for dosing of ingredients such as vitamins, flavours and colours directly into the main product stream. The compact skid provides a high degree of flexibility for the production of different products.

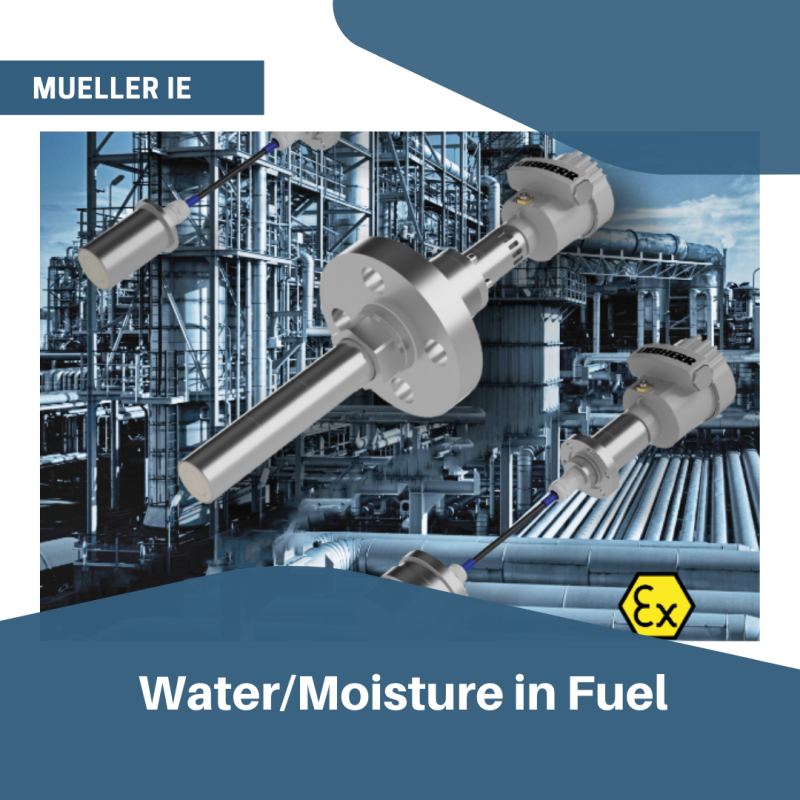

Water Content/Moisture Measurement in pipelines, fuel tanks, refineries

The new Liebherr Litronic WMS II Rod Sensor P45-GD for precise water concept/moisture determination in liquids with pressure and temperature measurement. Running process monitoring of

- Oil, crude oil, diesel, biodiesel, hardening oil

- Coolants, Paints, lacquers, solvents

- Wax, resin, emulsions, suspensions

in maritime industries, refineries, oil platforms, pipelines and chemical applications in Ex protected environments.